In today’s fast-paced industrial landscape, maximizing efficiency is crucial for maintaining competitive advantage. Low-voltage servo drives have emerged as a pivotal technology, enabling businesses to enhance operational performance while reducing energy consumption. This article explores the advantages of low-voltage servo drives and how they can transform your operations.

Understanding Low-Voltage Servo Drives

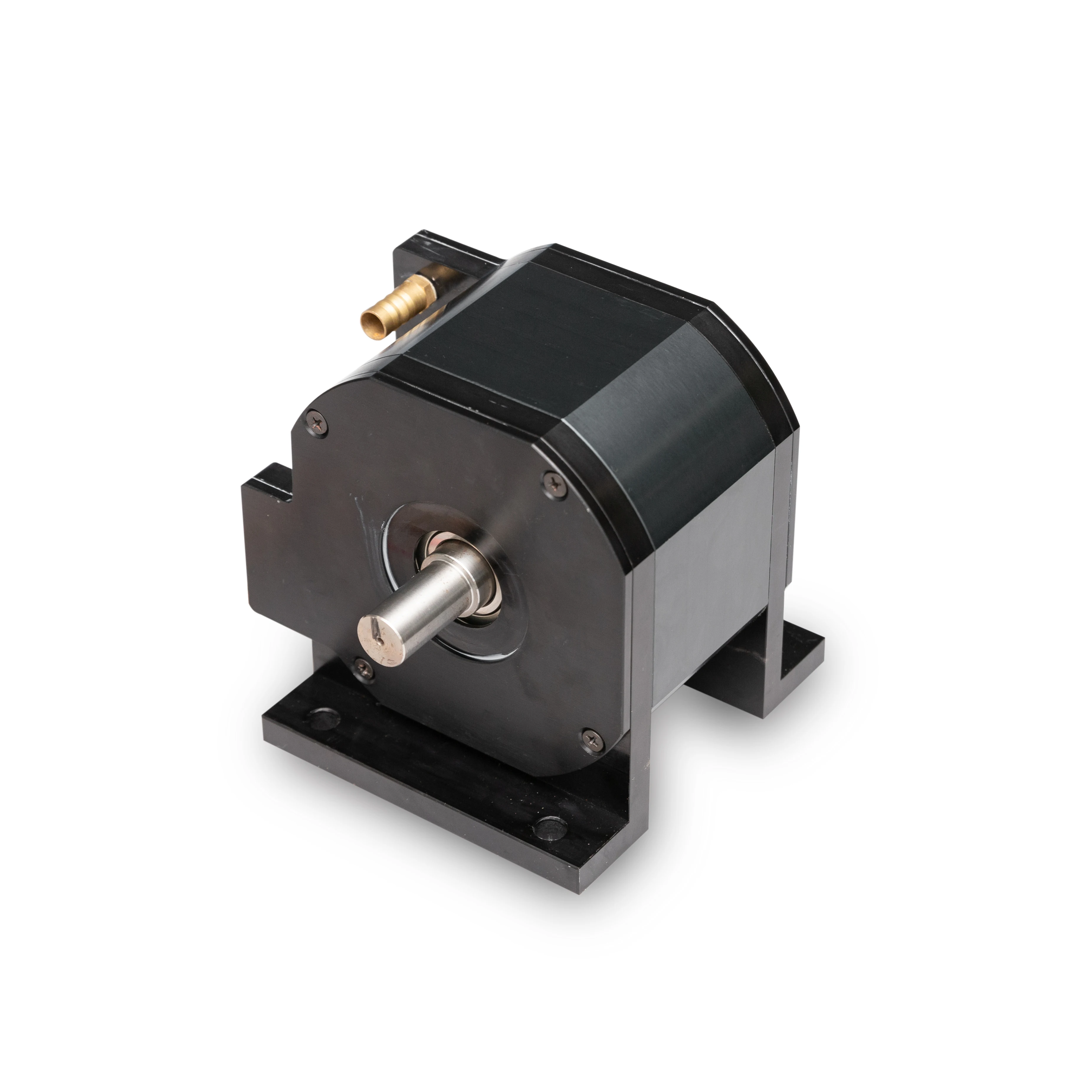

Low-voltage servo drives are designed to control the movement of motors with precision and efficiency. Unlike traditional drives, these systems operate at lower voltage levels, making them safer and more energy-efficient. By utilizing advanced control algorithms, low-voltage servo drives can significantly improve the responsiveness and accuracy of machinery, which is essential in applications ranging from robotics to manufacturing.

Benefits of Low-Voltage Servo Drives

One of the primary advantages of low-voltage servo drives is their ability to reduce energy consumption. By optimizing motor performance and minimizing waste, these drives can lead to substantial cost savings over time. Additionally, the compact design of low-voltage servo drives allows for easier integration into existing systems, making upgrades straightforward and less disruptive.

Furthermore, low-voltage servo drives contribute to enhanced operational reliability. With fewer components and lower heat generation, these systems tend to have longer lifespans and require less maintenance. This reliability translates into reduced downtime and increased productivity, allowing businesses to meet customer demands more effectively.

Applications of Low-Voltage Servo Drives

Low-voltage servo drives are versatile and can be applied across various industries. In manufacturing, they are used to control conveyor systems, CNC machines, and robotic arms, providing precise motion control that enhances production efficiency. In the automotive sector, these drives facilitate the automation of assembly lines, ensuring consistent quality and speed.

Moreover, low-voltage servo drives are increasingly being adopted in renewable energy applications, such as wind and solar power systems. Their efficiency helps optimize the performance of these installations, contributing to a more sustainable energy future.

Conclusion

In conclusion, low-voltage servo drives are a game-changer for industries seeking to maximize efficiency and reduce operational costs. Their energy-saving capabilities, reliability, and versatility make them an ideal choice for a wide range of applications. By investing in low-voltage servo drives, businesses can enhance productivity, ensure operational reliability, and ultimately achieve a competitive edge in the market.