In the pharmaceutical, biotechnology, and electronics industries, clean rooms are essential for maintaining controlled environments. A crucial aspect of clean room design is the flooring, which must meet various standards for cleanliness, durability, and safety. This article will explore the essential factors to consider when selecting clean room flooring.

Understanding Clean Room Requirements

Before delving into specific flooring options, it's essential to understand the requirements of a clean room. Clean rooms are classified based on the level of contamination they can tolerate, typically measured in terms of particles per cubic meter. Factors such as the type of industry, the processes conducted, and the required cleanliness levels dictate the clean room's design, including its flooring.

Key Considerations for Clean Room Flooring

When selecting flooring for clean rooms, several factors must be taken into account:

1. Cleanliness Standards

The flooring material should not contribute to contamination. It must be easy to clean and resistant to microbial growth. Non-porous materials that can withstand frequent cleaning and disinfection are often preferred.

2. Durability and Load-Bearing Capacity

Clean room flooring must be able to support heavy equipment and foot traffic. The flooring material should be durable enough to withstand wear and tear without compromising its integrity.

3. Static Control

In environments like server rooms, the best anti-static floor for server room is critical to prevent damage to sensitive electronic equipment. Proper grounding and material selection can mitigate static electricity issues.

4. Comfort and Safety

For facilities with personnel frequently moving about, comfort is a factor. Anti-fatigue mats or cushioned flooring can help reduce strain on workers. Additionally, the flooring should provide slip resistance to prevent accidents.

Types of Clean Room Flooring

Various flooring options are available, each with its unique advantages and disadvantages:

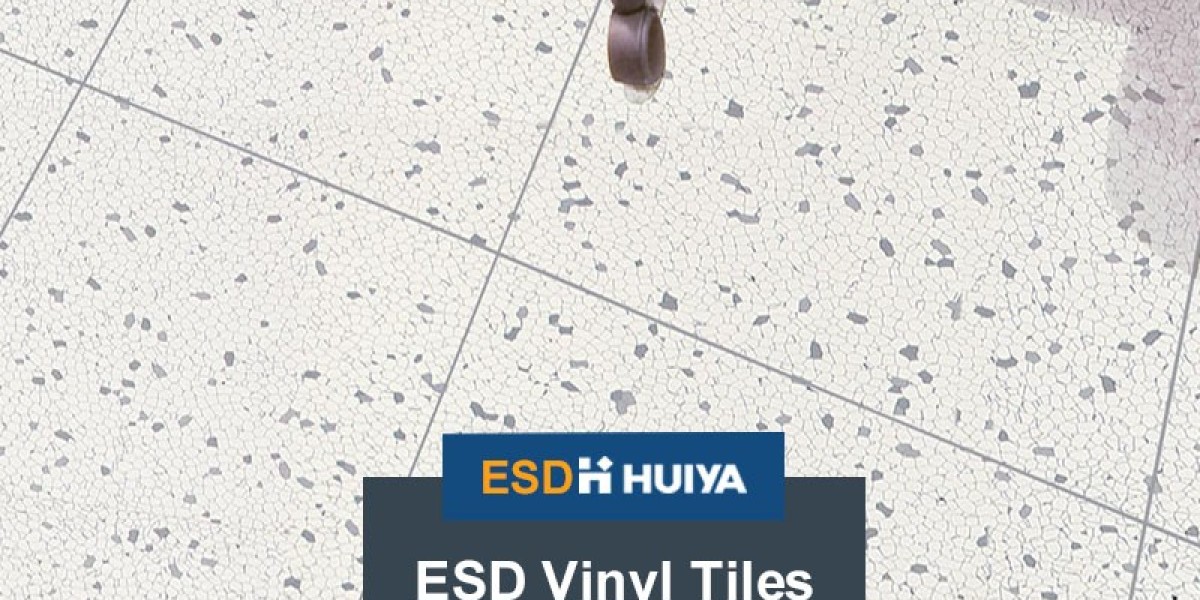

1. Vinyl Flooring

Vinyl is a popular choice due to its non-porous surface and ease of cleaning. It can be installed as sheets or tiles, providing flexibility in design. However, it may not be as durable under heavy loads as other materials.

2. Epoxy Flooring

Epoxy coatings provide a seamless and durable surface that is resistant to chemicals and staining. They are ideal for areas with heavy machinery or foot traffic, but installation can be time-consuming and requires proper curing time.

3. Raised Access Floors

Using clean room access floor systems allows for easy access to utilities beneath the floor. This type of flooring is particularly beneficial in environments where frequent maintenance is required.

4. Tiles

Tiles can be made from various materials, including ceramic and rubber. They are generally easy to replace if damaged, making them a practical choice. However, grout lines can harbor bacteria if not properly maintained.

Installation Considerations

The installation process of clean room flooring is critical to ensure it meets the required standards. Some important aspects include:

1. Surface Preparation

Before installation, the subfloor must be properly prepared to ensure adhesion and longevity. This may involve leveling and cleaning the surface to eliminate contaminants.

2. Installation Techniques

Different materials require specific installation techniques. For instance, epoxy needs to be mixed and applied under controlled conditions, while tiles may require precise alignment.

3. Post-Installation Testing

After installation, the flooring should undergo testing to ensure it meets cleanliness and performance standards. This may include air quality tests and surface contamination checks.

Maintaining Clean Room Flooring

Once installed, maintaining the flooring is crucial to ensure it continues to meet clean room standards. Regular cleaning schedules, appropriate cleaning agents, and inspections for wear and tear are essential.

For more detailed guidance on clean room flooring options, you can refer to this comprehensive resource.

Selecting the right clean room flooring is vital for operational efficiency and maintaining stringent cleanliness standards. By understanding the unique requirements of your clean room and evaluating the various flooring options available, you can make an informed decision that enhances both safety and performance in your facility.