The Biodiesel Manufacturing Plant Project Report provides an in-depth analysis of the production process, market potential, and key considerations for establishing a biodiesel manufacturing facility. Biodiesel is an eco-friendly and sustainable alternative to conventional fossil fuels, derived from vegetable oils, animal fats, or used cooking oil. With the increasing emphasis on reducing carbon footprints and dependency on non-renewable energy sources, the demand for biodiesel has surged globally. Establishing a biodiesel manufacturing plant presents a lucrative opportunity in the renewable energy sector, contributing to environmental sustainability and energy security.

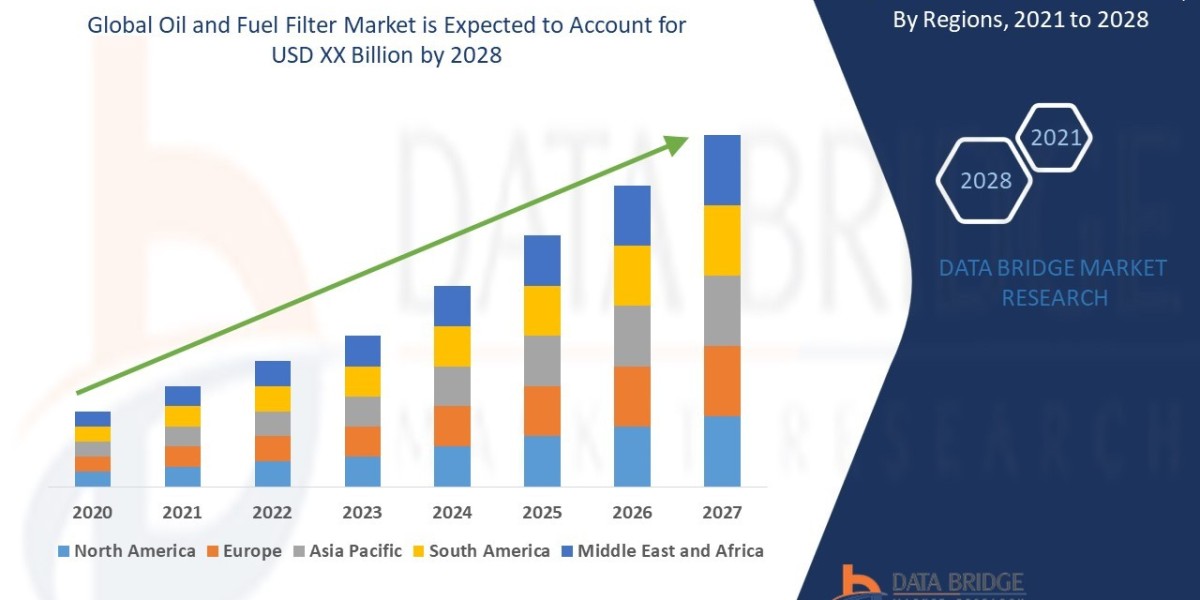

Market Demand and Growth Prospects

The demand for biodiesel has seen a steady rise, driven by government policies promoting clean energy, rising crude oil prices, and growing environmental concerns. Many countries have introduced mandates requiring the blending of biodiesel with conventional diesel to lower emissions and enhance fuel efficiency. Additionally, the shift toward renewable energy sources in the transportation and industrial sectors has further propelled market growth.

Biodiesel is widely used in industries such as automotive, agriculture, marine, and power generation. Its biodegradable and non-toxic nature makes it a preferred alternative in environmentally conscious economies. The increasing global focus on achieving carbon neutrality and promoting green energy solutions creates a favorable market for biodiesel manufacturers. Research and development efforts in feedstock optimization and production efficiency continue to improve the viability and profitability of biodiesel manufacturing.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/biodiesel-manufacturing-plant-project-report/requestsample

Raw Materials and Procurement

Setting up a Biodiesel Manufacturing Plant requires a consistent supply of raw materials, including vegetable oils (soybean, palm, rapeseed), animal fats, and recycled cooking oil. The quality and availability of feedstock play a crucial role in determining production efficiency and cost-effectiveness.

Strategic partnerships with suppliers, farmers, and waste oil collectors help in maintaining a steady flow of raw materials. Additionally, advancements in feedstock diversification, such as the use of algae-based oils and non-food crops, provide sustainable alternatives for biodiesel production. Establishing a well-structured procurement system ensures smooth operations and minimizes supply chain disruptions.

Manufacturing Process

The production of biodiesel involves a chemical process known as transesterification, where triglycerides from oils or fats react with an alcohol (usually methanol) in the presence of a catalyst to form biodiesel and glycerin as a byproduct. The general manufacturing process includes the following steps:

- Feedstock Preparation – The raw material is filtered and pretreated to remove impurities and excess moisture.

- Transesterification Reaction – The processed feedstock is mixed with alcohol and a catalyst, typically sodium or potassium hydroxide, to initiate the chemical reaction.

- Separation and Purification – After the reaction, the biodiesel is separated from glycerin and further purified to meet industry standards.

- Quality Testing and Storage – The final product undergoes rigorous quality testing before being stored in appropriate containers for distribution.

Quality Standards and Compliance

Biodiesel production must adhere to stringent quality standards to ensure compatibility with diesel engines and environmental compliance. Regulatory frameworks such as ASTM D6751 (USA) and EN 14214 (Europe) define the specifications for biodiesel quality. Maintaining proper blending ratios, testing for impurities, and ensuring compliance with emission norms are crucial aspects of production.

Environmental regulations mandate proper waste disposal and emission control measures during the manufacturing process. Investing in advanced purification technologies and adhering to sustainable practices can enhance the credibility and market acceptance of biodiesel products.

Marketing and Distribution Strategies

For the successful operation of a Biodiesel Manufacturing Plant, a robust marketing and distribution strategy is essential. Target markets include fuel retailers, transportation companies, agricultural sectors, and government bodies promoting biofuel adoption.

Collaboration with oil distribution networks, vehicle manufacturers, and fleet operators can create a steady demand for biodiesel. Digital marketing, industry conferences, and participation in renewable energy trade fairs help in establishing brand presence and consumer trust. Expanding into export markets and developing customized fuel solutions for different industries further enhances business growth.

Future Outlook and Opportunities

The biodiesel industry is poised for substantial growth with increasing investments in renewable energy and biofuel research. Technological innovations in feedstock processing, enzyme-based catalysis, and waste-to-biofuel conversion are expected to enhance production efficiency and cost-effectiveness. Governments worldwide are promoting policies supporting biofuel adoption, further boosting the market potential for biodiesel manufacturers.

Manufacturers focusing on sustainable sourcing, advanced production techniques, and regulatory compliance will gain a competitive edge in the evolving biodiesel market. As the world moves toward cleaner energy solutions, the biodiesel industry presents promising opportunities for long-term profitability and environmental impact reduction.