How Modern Cheese Shredders Are Reshaping Food Processing Lines

Efficient, Hygienic, and Diverse: How Modern Cheese Shredders Are Reshaping Food Processing Lines

In the catering and food processing industries, cheese processing efficiency and quality directly impact product speed, cost control, and final flavor. Manual shredding is not only inefficient and results in uneven thickness, but also poses food safety and labor cost risks. Therefore, cheese shredders have become an indispensable core piece of equipment in modern kitchens and food factories.

I. Core Working Principle

A cheese shredder uses a motor to drive a built-in rotating cutter drum equipped with precision-designed blades. When cheese blocks are fed into a hopper, they are forced against the rotating cutter drum under the steady pressure of an augmenter, resulting in uniform shreds, slices, strips, or shreds. The entire process is continuous and automated, ensuring highly consistent product quality.

II. Main Types and Options

Vertical Feed Shredder

Features: Suitable for processing hard, easy-to-grip cheese blocks (such as cheddar and mozzarella). Advantages: Compact structure, intuitive operation, and easy cleaning and blade replacement.

Horizontal Feed Shredder

Features: Utilizing a horizontal feed screw, it's suitable for processing large quantities of cheese of varying hardness, even slightly sticky cheeses.

Advantages: Extremely high production capacity and a high degree of automation. Often connected to a conveyor belt to form a production line, it's the preferred choice for large-scale food processing plants.

Combi Shredder

Features: A single machine can quickly switch between multiple blades, performing various functions such as shredding, slicing, strip cutting, and shredding.

Advantages: A single machine offers multiple uses, saving space and investment, making it ideal for environments requiring a diverse product range, such as central kitchens and pizzerias.

III. Advantages and Value

Extreme Efficiency and Cost Reduction:

A medium-sized shredder can process hundreds of kilograms of cheese per hour, achieving efficiency dozens of times greater than manual labor, significantly reducing labor and time costs.

Uniform Output and Stable Quality:

Ensuring consistent size, shape, and weight for each product is crucial for optimal cooking meltability, product appearance, and standardized packaging. Highly hygienic, safe, and reliable:

The equipment is typically constructed of 304 or 316 grade stainless steel and complies with food safety standards (such as HACCP and CE). Its enclosed design and easy disassembly for cleaning effectively minimize contamination risks.

Reduced waste and increased yield:

The mechanical advancement design allows for near-complete utilization of cheese, leaving minimal residue. Compared to manual processing, this reduces waste and directly increases profit margins.

Versatile, multi-purpose machine:

By replacing different blade cylinders, you can easily produce:

Shreds: Thin and thick (suitable for pizza and salads)

Slices: (suitable for burgers and sandwiches)

Sticks: (suitable for snacks and salads)

Grates: (suitable for pasta and baking)

IV. Technical Parameter Selection Guide

When selecting a cheese shredder, consider the following key parameters:

Capacity: The amount of cheese processed per unit time

Power: Determines power and efficiency

Blade type: Determines the finished product shape

Material: Affects hygiene and durability

Feed port size: Limits cheese block size

Degree of automation: Whether to connect to a conveyor belt or weighing system

V. Wide range of applications

Large food processing plants: Used to produce pre-packaged mozzarella cheese, shredded cheese, and other products.

Central kitchens: Supply standardized cheese ingredients to pizza chains, Western restaurants, and fast food restaurants.

Large hotels and restaurants: Meet the high-volume needs of daily meal preparation. Cheese producers and repackers: Primary processing and packaging of large cheese wheels.

VI. Choosing a Reliable Partner

A high-quality cheese shredder is more than just a piece of equipment; it's a strategic investment that improves productivity and quality. Choosing a supplier with deep industry experience, customized solutions, and comprehensive after-sales service is crucial.

Weishu Technology (Shanghai) Co., Ltd., with over 20 years of technical expertise, not only provides stable and efficient standardized shredders but also offers customers a one-stop, turnkey cheese processing solution. This includes comprehensive services from initial consultation and equipment customization to installation, commissioning, and after-sales support, ensuring your equipment is always operating at peak performance.

In short, cheese shredders exemplify the pursuit of efficiency, standardization, and hygiene and safety in the modern food industry. Investing in the right shredder empowers your business, achieving the dual goals of cost reduction, efficiency improvement, and quality improvement.

📧Email: weishumachinery@weishujixie.com

📞WhatsApp/phone: +86 177 7527 7877

🌐Website:https://www.weishumachinery.com/

https://www.wfoodmachinery.com/

@SerenaWang

milk processing plant

A system that integrates vacuum deaerators, tubular uht sterilizers, and homogenizers, with fully automatic control, providing better processing performance for milk and juice.

If you want to know more information about this machine, please contact us through the following ways:

📧Email: weishumachinery@weishujixie.com

📞WhatsApp/phone: +86 177 7527 7877

🌐Website:https://www.weishumachinery.com/

https://www.wfoodmachinery.com/

Pneumatic cheese cubes cutting machine,cheese cutter

Pneumatic cheese cubes cutting machine,cheese cutter

It's a perfect cheese cutting tool, leveraging pneumatic force to create a smooth, evenly slicing blade. It cuts both hard and soft cheeses into perfectly square, evenly thick slices, eliminating the need for manual slicing. This reduces waste by half, ensuring each piece of cheese looks great. It starts with a single click, making it easy for even beginners to learn. The durable, food-grade stainless steel body ensures long-lasting results.

Any questions please contact us!

Below:

📧Email: weishumachinery@weishujixie.com

📞WhatsApp/phone: +86 177 7527 7877

🌐Website:https://www.weishumachinery.com/

https://www.wfoodmachinery.com/

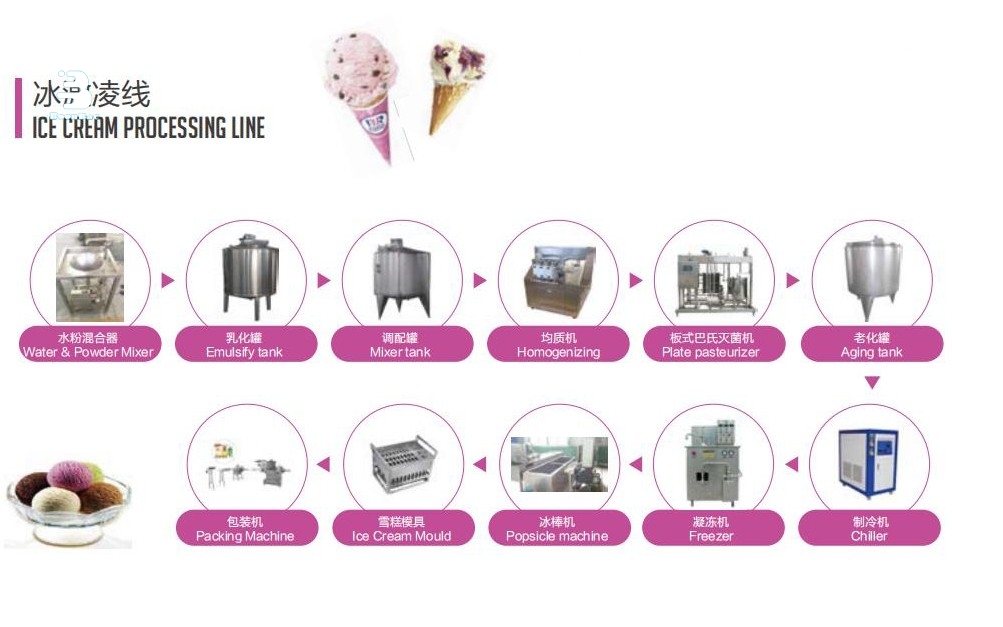

Our production solutions revolutionize ice cream production.

From fresh dairy ingredients to delicious scoops of ice cream, the entire process requires meticulous planning, and we specialize in creating advanced ice cream production solutions. Our comprehensive production lines ensure that every step in the ice cream-making process is executed with precision and efficiency, guaranteeing a delicious end product.

Our automated ice cream production lines are designed to meet the ever-changing needs of the ice cream industry. They encompass a range of equipment and processes, from raw material preparation to pasteurization, ice cream slush maturation, freezing, and packaging. The result is a seamless, end-to-end solution that sets a new standard in ice cream manufacturing. Our industrial ice cream machines are the heart of the production lines. These rugged machines are engineered to meet the demands of high-volume production, delivering exceptional performance, consistency, and reliability. To meet the evolving market demands, we developed our combination ice cream machine. This innovative unit integrates mixing, pasteurization, and maturation systems, seamlessly connecting with the ice cream machine and packaging machine, significantly reducing factory footprint. This space-saving solution is ideal for businesses looking to optimize production processes without compromising quality.

Why choose Weishu:

Fully automated production: Our fully automated ice cream machines are designed to minimize manual intervention, improve production efficiency, and enhance product consistency. Customized Solutions: We understand that every ice cream manufacturer is unique. Whether you produce cones, cups, or other flavors, we can provide a tailored solution to meet your specific production needs.

Comprehensive Production Lines: Our ice cream plant equipment includes all the components needed for a complete ice cream production solution, from preparation to packaging.

Quality Assurance: We prioritize quality and consistency, ensuring that every scoop of ice cream leaving your facility meets the highest standards of taste and safety.

At Weishu, we are committed to providing cutting-edge solutions for the ice cream industry. Our automated ice cream production lines, combined with innovative equipment packages, help you meet the demands of a rapidly evolving market. Contact us today to learn how our solutions can enhance your ice cream production process.👏

Tubular UHT sterilizer/ Tubular pasteurizer

Tubular UHT sterilizer/ Tubular pasteurizer

Description:

The tubular UHT sterilizer is designed for milk, juice, and tea beverages. It integrates heating, sterilization, cooling, and heat recovery, with a touchscreen displaying and recording real-time production data. It ensures ultra-high-temperature sterilization in a short time, preserving nutrients and color. Customizable for aseptic processes, it’s essential in the dairy industry.

Working principle:

The product is heated to 138-150 ℃ through a tubular heat exchanger in a continuous flow state and maintained at this temperature for a certain period of time (2-4 seconds) to achieve commercial sterility. Then, under sterile conditions, place it into a sterile packaging container in a sterile environment🧐

WeiShu Machinery Technology (Shanghai) Co., Ltd. is located in Fengxian District, Shanghai, China. We are a dairy beverage equipment manufacturer

integrating design, R & D, production, sales and service. We have more than 20 years of industry experience, professional formula technologists and

overseas installation teams. At present, our equipment is exported to all over the world. We sincerely look forward to cooperating with you!