What is Precision Molding?

This is a critical step in the production of various products, and precision molding is extremely important. It’s a lot of work to pay attention to that and nurture it into being exactly what you want. A new technology, known as 3KU, has revolutionized the way that molding is performed and helps manufacturers more accurately produce parts. In this article, let’s discuss the advantages of employing 3KU technology when doing precision 3d printing molding.

Why is precision molding necessary?

Precision molding is utilized in many sectors, from automobiles and electronics to medical devices. It contributes to the making of complex shapes that have to go together perfectly. That means manufacturers can get these shapes right and get them right fast with 3KU technology.

Benefits of 3KU Technology

One of the greatest advantages of using 3KU is that it can produce highly detailed shapes with a high precision. Special machines and software are used to make every part to the precise size required. This is crucial so all the bits bundle up and work in harmony.

Another one of the amazing things about 3KU is that it has helped to produce parts rapidly and with a high level of repeatability. Traditional molding processes can be time consuming and have errors which can lead to delays and waste money. “3KU enables manufacturers to make more parts faster, and better,” Muse said.

How 3KU is revolutionizing the Molding Industry

3KU technology has revolutionised the industry of molding. It offers a faster, more precise and less expensive process than traditional methods for making parts. By simplifying the precision 3d printing molding process and eliminating errors, 3KU makes it easier for manufacturers to produce high-quality parts more efficently.

3KU is also available with various materials and colors for manufacturers. That means they can generate the right part for what they need, whether it’s a strong part for a car or a light one for electronics.

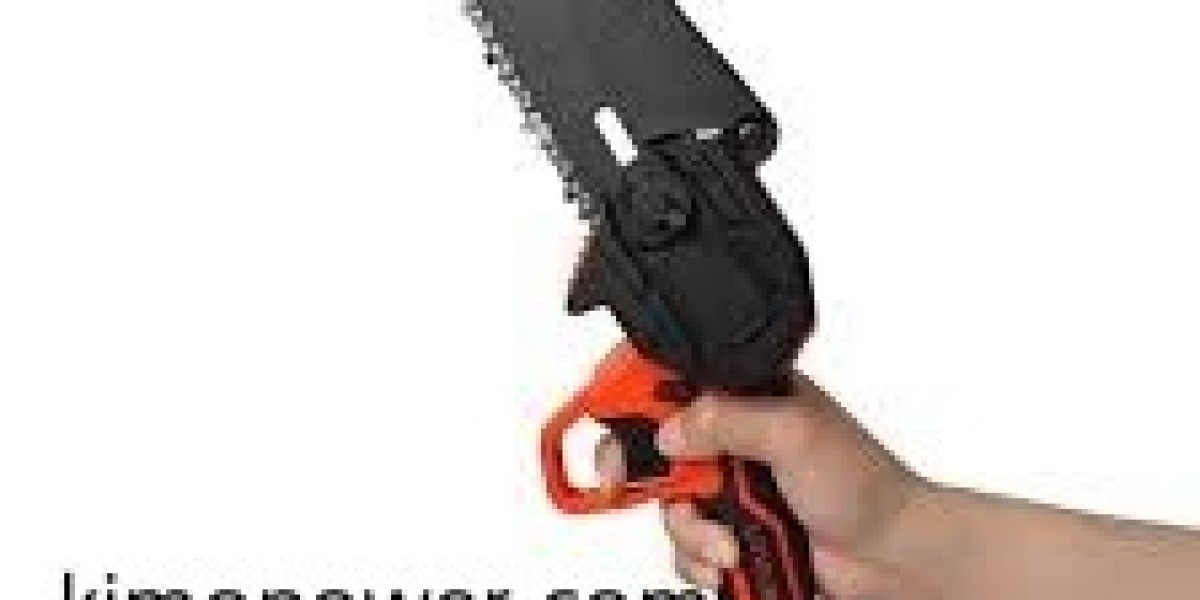

Case Study: Precision Molding with 3KUFigure 1: Adjusting 3R SlideUsing 3KU for Precision Molding

To illustrate how 3KU technology aids in precision molding, consider the following example. A Shenzhen manufacturer wanted to produce small parts for a new electronic device. They Utilized 3KU Technology By implementing 3KU technology you can effectively make all the parts with the maximum of accuracy so it fits perfectly. The high-tech equipment and software they had purchased made it easy to get the results they were looking for, quickly, and it saved them time and money.

New Avenues with 3KU Technology

3KU technology brings new possibilities to the mold industry for the manufacturers. Being able to 3D-print parts in high accuracy gives way to opportunities for new ideas and creativity. That enables them to make things that were difficult to make previously.

The nice thing about using 3KU is that it allows manufacturers to prototype quickly, and without investing a lot of money. This allows them to try out new ideas before producing a lot of product, which cuts down on mistakes and maintains quality.

Conclusion of the 3KU Case Study

4 Conclusion This case study is an example for the benefits of applying 3KU technology in precise 3d printer molding. Through a better molding process, the elimination of mistakes, and increased efficiency 3KU has revolutionized the industry. With technology constantly advancing, doors are being opened for precision molding with 3KU, and new ways to grow manufacturing with it are being unlocked every day.