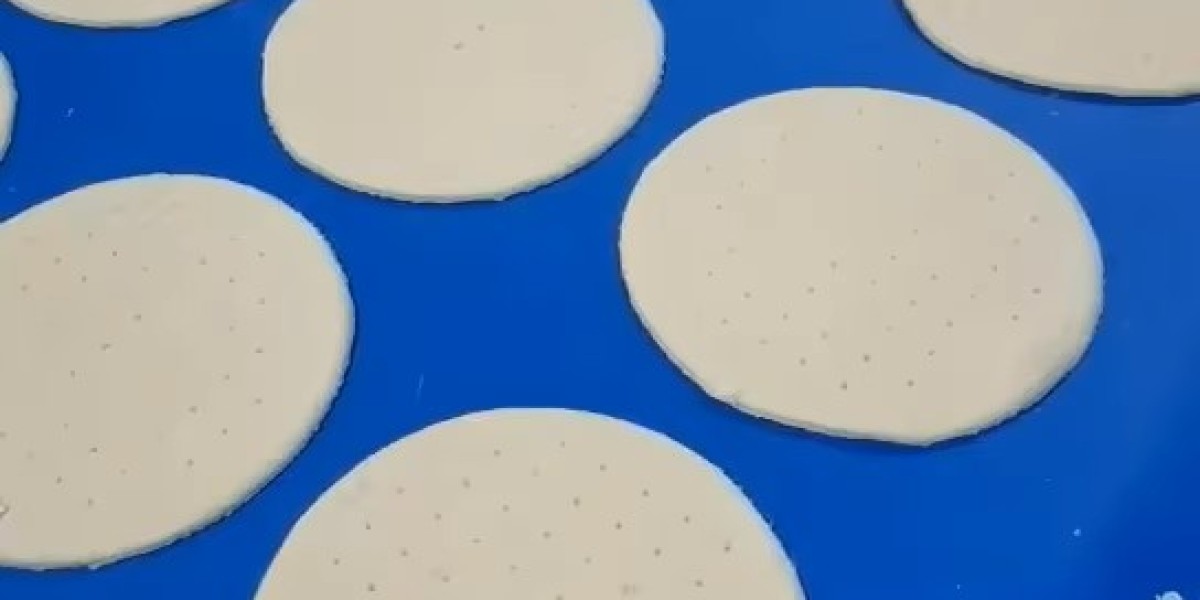

In modern web handling systems, precise tension and tracking are essential, and Banana Rollers are commonly used to maintain material alignment and reduce wrinkles in high-speed processing lines.

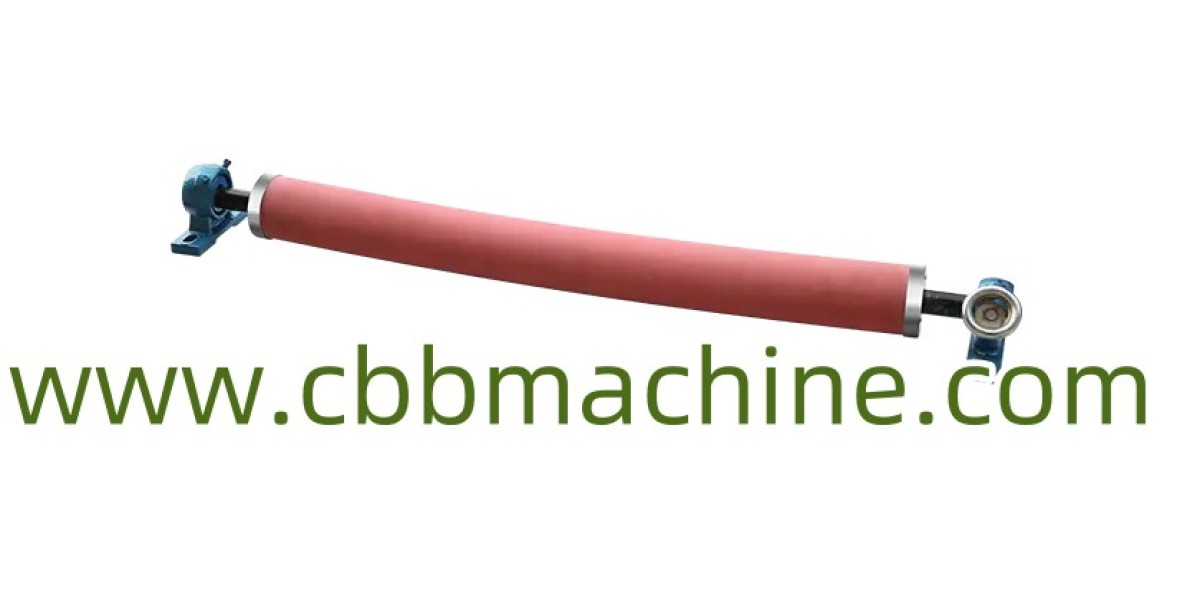

CBBMACHINE offers customized solutions for web spreading using arc-shaped rollers engineered for specific applications. These rollers are not generic components—they are calibrated to interact with different materials including plastic films, textiles, paper, and flexible laminates. Through careful design and testing, CBBMACHINE helps manufacturers eliminate common processing defects like folding, edge curling, or slack zones.

The key to their effectiveness lies in controlled curvature and balance. Unlike straight rollers, curved designs apply lateral forces that help the material stretch evenly as it moves forward. This minimizes distortions and improves downstream performance during slitting, coating, laminating, or rewinding operations.

CBBMACHINE constructs each roller with a lightweight aluminum or steel body depending on load requirements. Internally, precision bearings ensure low-friction rotation, even at high speeds. These elements are assembled under strict quality protocols to ensure concentricity, smooth operation, and extended service life.

Additionally, CBBMACHINE provides various surface finishes to match specific materials—smooth anodized for films, rubber-coated for delicate substrates, or grooved patterns for specialty uses. Optional adjustable brackets allow operators to modify the roller angle during operation, providing flexibility in web path control.

One of the unique offerings from CBBMACHINE is the option for modular roller systems that can be retrofitted into existing production lines. Whether a client is upgrading older equipment or designing a new line from scratch, these rollers integrate seamlessly and improve both material control and operational efficiency.

Maintenance is minimal, as the rollers are resistant to corrosion and engineered to withstand continuous use. With proper cleaning and periodic inspection, they remain reliable over long production cycles. For clients seeking technical support, CBBMACHINE offers consultation services to recommend roller dimensions, arc angles, and installation positions based on material type and machine layout.

For engineers and production managers aiming to enhance product quality and reduce waste, selecting the right roller solution is not just a mechanical choice—it’s a strategic one. CBBMACHINE continues to innovate in this field by combining custom fabrication, fast delivery, and expert service.

For detailed specs, custom quotes, and technical diagrams, visit https://www.cbbmachine.com/product/banana-roller/customizable-banana-roller.html