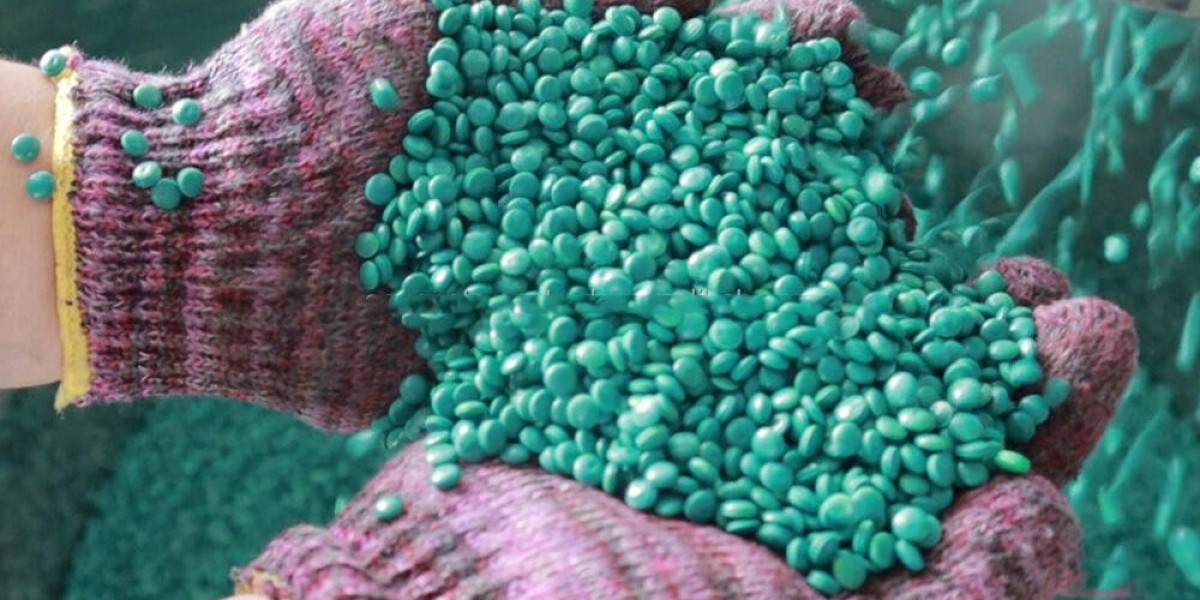

Wet Material Pelletizing Wet material pelletizing A cool pelletizer is a great machine that can take wet materials and convert them into small pellets that you can use as you see fit. Ever wondered how that happens? The cool things for your wet material pet pelletizing lines, and what makes SEVENSTARS MACHINERY takes critical part in it!

Physico-chemical mechanism of wet material pelletizing

For wet material pelletization, two processes are involved: physical and chemical. The mechanical process of combining the wet material with other materials (like binders, fillers, etc.) to achieve a uniform blend. This blend is lead into a pellet machine, wherein it is compressed by heat into a pellet. The other phenomenon is similarly a chemical process characterized by the combination of the wet ore particulate with the binding additive whereby the pellets are bound together. These operations are complemented by equipment designed to produce high quality pellets versatile and easy to manage for their applications.

A look at the Equipment and technology of wet material pelletizing lines

SEVENSTARS MACHINERY uses high quality technology and parts to manufacturing wet material pelletizing machine line with high performance and high efficiency. Pelletizing line typically consists of mixers, tumbling type pelletizers, air dryers, and air coolers. Wet mixers blend the wet material and binders and additives, and pelletizers form the mixture into briquettes. Pellet dryers take the excess moisture off the pellets and coolers reduce the temperature for storage and transport. These parts of the machine work well together to develop high quality pellets.

Moisture content and binder additives on optimum quality of pellets

The moisture and the binder additives are very important for the formation of high quality pellets. The wet material moisture level also has a bearing on the binding capability of the mixture and the pelletization process. Excessive moisture can make for weak pellets, too little may make pellets crumble. Binder additives, however, assist in increasing the strength and resistance of the pellets. SEVENSTARS MACHINERY makes careful moisture content and binder additives controll to produce good quality pellets every time.

Importance of equipment maintenance and calibration in wet pelletizing An understanding perspective

Thorough maintenance and calibration of equipment is crucial for the performance of wet pelletizing lines. Operator maintenance checks identify and prevent possible problems with the equipment and keep your operation running with less down time. In addition, calibration of the device is also important for precise and uniform pellet formation. SEVENSTARS MACHINERY pays much attention to the cooling and calibration of the pelletizing lines to guarantee high working efficiency and reliable pellets output.

Wet material granulating based on scientific principle and technology to make more efficient and effectively.prod.materials granulation.

SEVENSTARS MACHINERY utilizes science and technology to produce and maximize the performance and the output of wet material (sludge, etc.) pelletizing. By keeping a close eye on the various operations and factors, including temperature, pressure, and feed rate, they can tune the pelletizing process for peak output. Furthermore, ongoing R&D activity tends to enhance the pelletizing technology with higher and better quality pellets, while achieving higher productivity. SEVENSTARS MACHINERY is committed to pushing the limits of wet material pelletizing with forward thinking and scientific solutions.

In summary, wet material pelletizing extruder is a quite complicated and amazing process, it really calls for technology, knowledge and precision of manufacturing practice. SEVENSTARS MACHINERY is leading the industry, providing high quality machinery and excellent service for the wet material pelletizing. Through material physics and chemical analysis, research of the principles and technologies of main parts and technical parameters, and adjustment of moisture and binder additives, right maintenance, calibration and skilled operation, Sevenstars Machinery keep the leading position in wet material pelletizing field. SEVENSTARS MACHINERY is revolutionizing the way we produce pellet production by designing equipment that is dedicated to performance, production and quality.