Forged cylinder is a crucial component widely used in various machines to enable them function correctly. It will use key technologies to forge cylinders. At Hunan Jetvision Industrial Co, we know how to build forged cylinder in high quality which is strong, last long and most important: good appearance.

Realizing the significance of forging technology in the production of cyclinders

The forging technology is the method that uses the application of pressure to a metal and creates object from metal. That helps the metal become stronger and more durable. Forging technology is also very important for forging cylinders. We apply the forging technology to improve the size and shape for the cylinder. This contributes to the strength and dependability of our forged cylinders.

Investigating the heat treatment to secure the strength of reinforced cylinders

Heat Treatment Following the forging of the material by an open die forge, a heat treatment further increases the strength. Heat treatment is processing metal by heating it at very high temperatures, cooling it down gradually. This process is what makes that metal even stronger and more resistant to wear and tear, in turn making the forged cylinders stronger and longer lasting. Heat treatment is of high importance at Hunan Jetvision in order to guarantee the strength of our forged cylinders.

The role of precision machining in the production of high quality forge cylinders

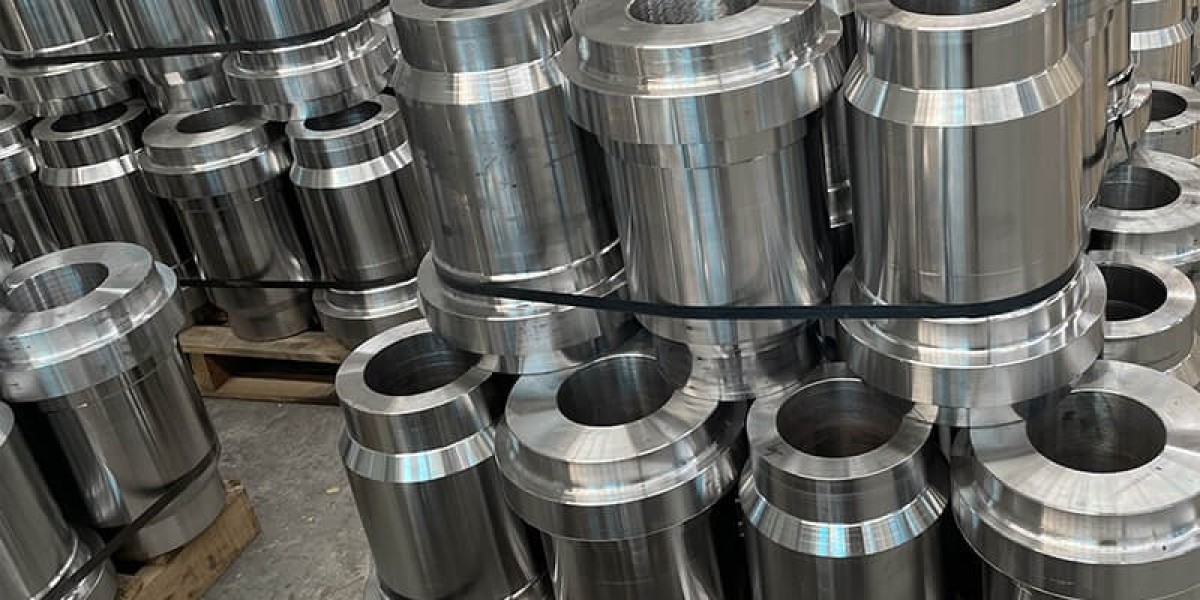

After the metal has been formed and heat treated, one needs precision machining to ensure that the forged cylinder are precisely the right size and shape. Part of precision machines the process where metal is cut in very accurate milling is. This helps to ensure that the cast cylinders are manufactured in such a manner that they will function properly. At Hunan Jetvision Industrial Co.,Ltd, we carry out the cutting, heat treating, cnc machining, straightening, powder coating and painting all in-house to ensure you receive the high-quality forged cylinders you deserve.

Advanced metallurgical analysis applied to quality control of forgings for cylinders

We use state-of-the-art metallurgical analysis to keep quality in check for our forged cylinders. With this technology we can test the metal that is used in the forged cylinders to ensure that it is strong, reliable and can withstand whatever we put our engine through. Through metallurgical analysis we can be confident that our forged cylinders are safe to use and with so long a service life. At Hunan Jetvision we’re about more than just pipes and tubes, we’re about perfection, and that starts with quality control from the ground up.With Jetvision, you can get the quality you need at a price you can afford.

Paving the way forward in fully automated and robotic forged cylinder production developments

In our quest of staying on top of the latest advancements in technology, we constantly strive to find new methods to enhance the production of our 42CrMo forged cylinder. Automation and robotics is one of the most exciting and innovative developments in this sector. Thanks to these technologies, now we can automatize many of the operations of the forged cylinders, having a faster and efficient processing. "We can produce engineered forgings at a faster rate and at reduced costs using automation and robots. We are constantly looking for ways to improve our manufacturing process and adopt the latest technologies.

In summary, There are numerous important technologies for the production of forged pressure vessels. Through enhancing our forging technology, heat treatment, precision machining, state-of-the-art metallurgical analysis, and investment in automation and robotics, we are able to develop high-quality forged cylinders that are strong and dependable. Hunan Jetvision utilise ces technologies pour fabriquer les meilleures culasses forgées possibles.