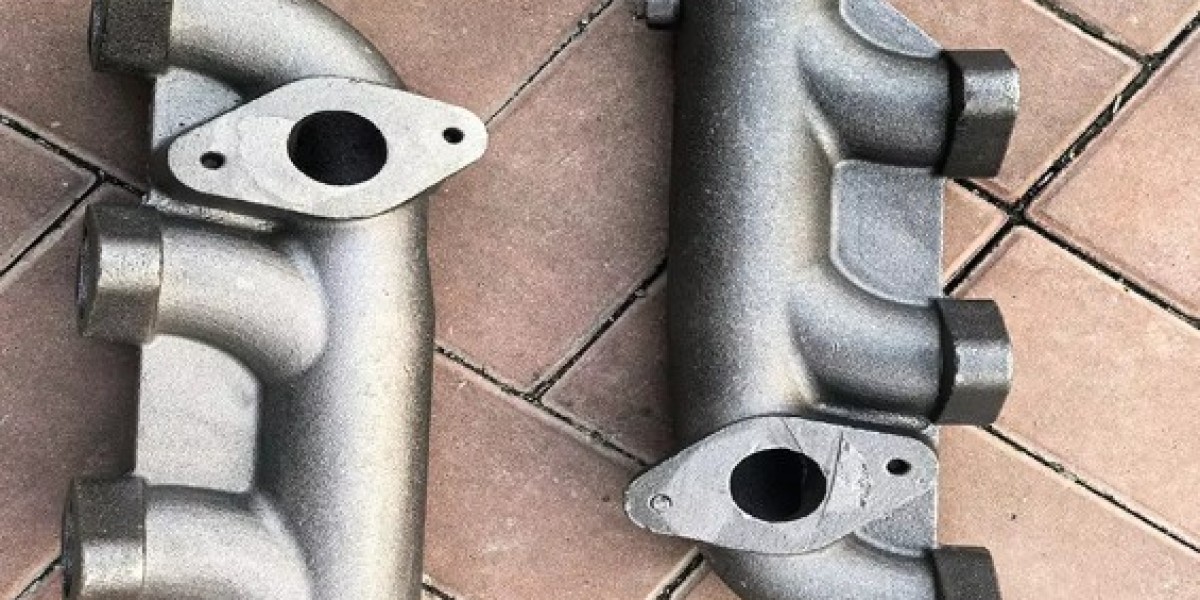

Pengxin uses iron sand casting to produce molten iron in a metal piece by the use of pouring hot on sand shaped as mold. This practice is versatile in nature and allows an economical approach to casting products, however, it may also lead to occurrence of defects in the final product as well., we will focus on some typical problems with respect to the iron sand castings method and ways to resolve them.

How Iron Sand Castings Surface Defects Are Found And Corrected

When a metal part is cast in the ductile nodular iron sand casting process, the surface of the metal can become imperfect in various ways – it can be too rough or have cracks in them and so on. Pengxin relies on visual inspections to determine these cases and apply these methods to detect non-destructive testing nodes. If the defects are detected, they can be rectified by using grinding, sandblasting or welds. This will help to make the surface imperfections go away so you can be certain your final product will be of good quality and that it will work well over time.

Shrinkage defect mechanism and solutions in iron sand casting process

Faulty cooling or inadequate feeding of molten metal can also lead to voids or cavities in the cast part and are referred to as shrinkage defects. Shrinkage defects are counteracted by modifying the gating system, adjusting the cooling rate and using risers to feed the molten metal (Pengxin). Shrinkage defects can be eliminated or minimized by controlling the casting process and making proper adjustments.

Ways to mitigate porosity in iron sand castings:

Presence of small pores, or air bubbles can change the mechanical properties of a cast part, and also look unsightly. Pengxin takes some measures to avoid the porosity, such as degasing of molten metal, good mold coatings and improving pouring, solidification process. Pengxin takes these measures to guarantee the final cast parts free from porosity and all of them up standard.

Common Dimensional Inaccuracies of Iron Sand Cast Parts & Possible Resolutions

During the cast nodular iron sand casting process, there may be dimensional inaccuracies like warping and variations in wall thickness. In view of this, in order to solve these kind of problems, Pengxin adopts the solution that it strictly control the mold temperature; it uses precise pattern equipment and carry out post-casting machining. Pengxin use it to maintain strict tolerances and watch the casting parameters all along the length of every valve, allowing us to ship valves that meet or exceed the final size in both inch dimensions and metric units.

To the point – Cracking and defects in iron sand cast components:

Iron sand cast components will not be free from any structural defects that are common in other castes, the integrity of which may affect cracking or some of the factors such as inclusion and cold shuts. To counter these, Pengxin manufactures with good quality raw materials, has control on the rate of cooling and implements good heat treatment process. Pengxin passes through the complex inspection and testing process to find out hidden defects in structure then correct it to ensure that every cast component is strong and durable enough.

Overall, to ensure proper ductile cast iron sand casting, it means you need to have good technical skills and expertise in troubleshooting process defects in gray iron casting by using preventive measures and monitoring. Pengxin ensures the quality and reliability of their cast parts by detecting and eliminating surface imperfections, shrinkage defects, porosity issues, dimensional inaccuracies, and structural defects. The investment and improvement over the years in its casting processes and quality controls makes Pengxin a reliable supplier of iron sand castings to several industries.