In the ever-evolving world of electrical engineering, the need for reliable and efficient connections is paramount. Parallel groove clamps have emerged as a crucial component in ensuring that electrical connections are not only secure but also capable of handling high currents with minimal resistance. This article delves into the advantages and applications of parallel groove clamps, highlighting their importance in various electrical setups.

Understanding Parallel Groove Clamps

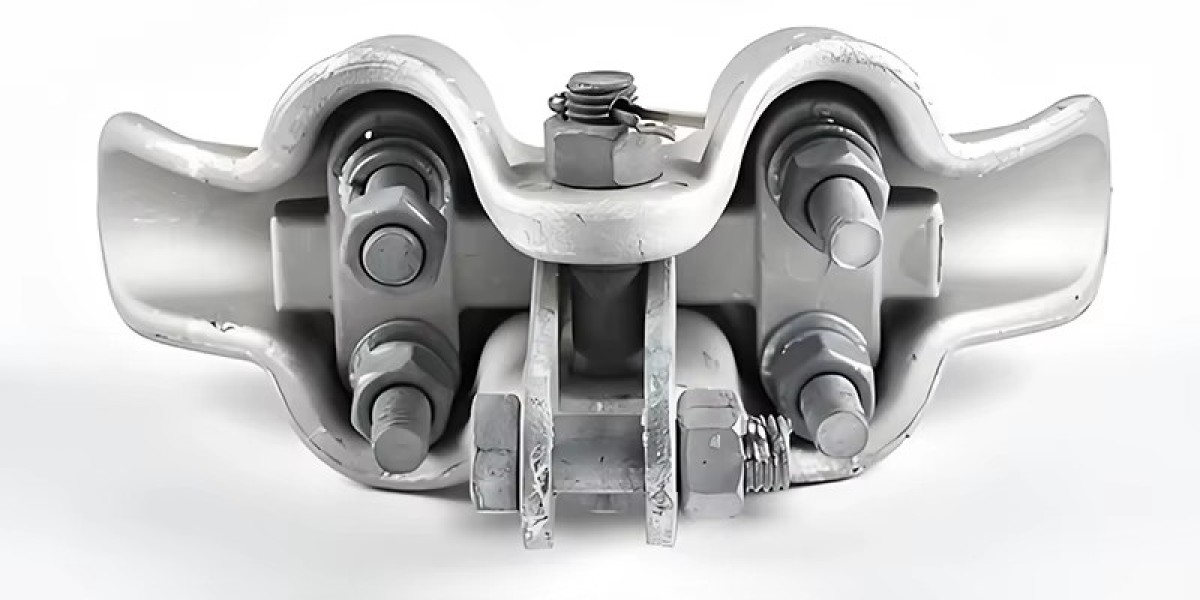

Parallel groove clamps are designed to connect two or more conductors in a parallel configuration. This design allows for a more efficient transfer of electrical current, making them ideal for use in power distribution, telecommunications, and renewable energy applications. The clamps are typically made from high-quality materials such as aluminum or copper, which enhance conductivity and durability. Their ability to accommodate different conductor sizes also makes them versatile for various applications.

Advantages of Using Parallel Groove Clamps

One of the primary advantages of parallel groove clamps is their ability to provide a strong mechanical connection. This ensures that the conductors remain securely fastened, reducing the risk of connection failure due to vibration or thermal expansion. Additionally, these clamps offer low contact resistance, which is essential for maintaining efficient electrical performance. By minimizing energy loss during transmission, parallel groove clamps contribute to the overall efficiency of electrical systems.

Applications in Various Industries

Parallel groove clamps are widely used across several industries, including construction, utility services, and renewable energy sectors. In construction, they are often employed to connect overhead power lines, ensuring that electrical systems can withstand environmental factors. In utility services, these clamps play a vital role in maintaining the integrity of power distribution networks. Furthermore, with the rise of renewable energy sources such as solar and wind, parallel groove clamps are increasingly being used to establish reliable connections in these systems, facilitating the transition to sustainable energy solutions.

Installation and Maintenance Considerations

Proper installation of parallel groove clamps is crucial for optimal performance. It is essential to follow manufacturer guidelines to ensure that the clamps are tightened to the correct torque specifications. Regular maintenance should also be conducted to inspect for any signs of wear or corrosion, particularly in outdoor applications. By adhering to these practices, users can significantly extend the lifespan of their electrical connections and enhance the reliability of their systems.

Conclusion

In summary, parallel groove clamps are an indispensable tool for ensuring efficient electrical connections across various applications. Their robust design, low contact resistance, and versatility make them a preferred choice for engineers and technicians. By investing in high-quality parallel groove clamps, businesses can enhance the reliability and performance of their electrical systems, ultimately leading to improved operational efficiency and reduced downtime.