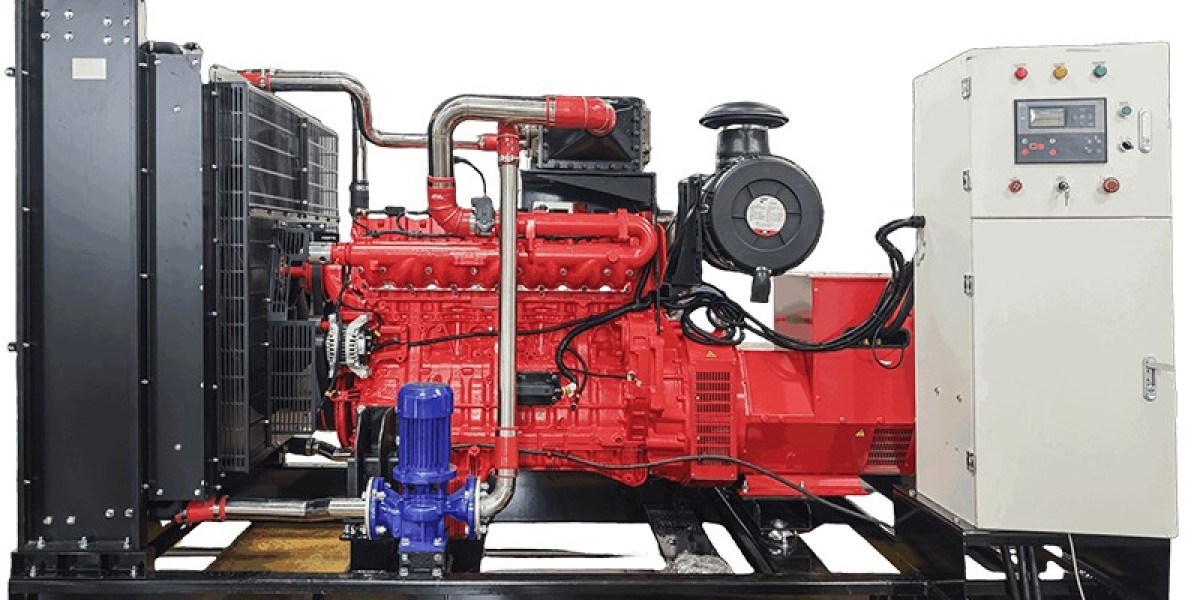

Regular Inspection of Methanol Generator Fuel System

The fuel system is the heart of a methanol generator, so regular inspection is a must - do for maintenance. First, you need to check the fuel tank regularly. Look for any signs of leakage, corrosion, or dirt inside the tank. Even small leaks can lead to fuel waste and even safety hazards. Then, inspect the fuel lines. Make sure there are no cracks, bulges, or loose connections. If the fuel lines are damaged, methanol may leak, which not only affects the generator's performance but also poses a risk of fire. Additionally, don't forget to check the fuel filter. A clogged fuel filter can block the flow of methanol, causing the generator to run poorly or even stop working. It's recommended to replace the fuel filter according to the manufacturer's guidelines to keep the fuel system clean.

Checking and Maintaining Methanol Generator Engine Oil

Engine oil plays a crucial role in lubricating the moving parts of a methanol generator's engine, reducing friction and wear. So, checking and maintaining the engine oil is an important part of maintenance. First, you should check the oil level regularly. Turn off the generator and wait for a few minutes to let the oil settle. Then, pull out the oil dipstick, wipe it clean, reinsert it fully, and pull it out again to check the oil level. If the oil level is below the recommended mark, add the appropriate type of oil. Next, check the oil quality. If the oil looks dark, dirty, or has a strange smell, it's time to change the oil. Old and dirty oil can't lubricate the engine properly, which may lead to increased engine wear and reduced performance. Remember to follow the manufacturer's instructions on the frequency of oil changes and the type of oil to use.

Cleaning Methanol Generator Air Filter

The air filter of a methanol generator prevents dust, dirt, and other debris from entering the engine, ensuring that the engine gets clean air for combustion. A dirty air filter can restrict the air flow, leading to incomplete combustion, reduced fuel efficiency, and even damage to the engine. So, cleaning the air filter regularly is essential. First, locate the air filter housing, which is usually on the side or top of the engine. Open the housing and take out the air filter. If the air filter is made of foam, you can clean it with warm soapy water, rinse it thoroughly, and let it dry completely before reinstalling. If it's a paper air filter, check if it's too dirty. If it's only slightly dusty, you can tap it gently to remove the dust. But if it's heavily soiled, it's better to replace it with a new one. Make sure to reinstall the air filter properly to prevent unfiltered air from entering the engine.

Inspecting Methanol Generator Electrical System

The electrical system of a methanol generator includes the battery, spark plug, wires, and other components, which are vital for starting the generator and ensuring its normal operation. So, inspecting the electrical system regularly is necessary. First, check the battery. If the generator has a lead - acid battery, check the electrolyte level. If it's low, add distilled water to bring it up to the recommended level. Also, check the battery terminals for corrosion. If there's corrosion, clean it with a wire brush and apply a thin layer of petroleum jelly to prevent further corrosion. Then, inspect the spark plug. Remove the spark plug and check its condition. If the electrode is worn, dirty, or has carbon deposits, clean it with a wire brush or replace it if necessary. Additionally, check the electrical wires and connections. Make sure the wires are not damaged, and the connections are tight. Loose or damaged wires can cause the generator to fail to start or run intermittently.

In conclusion, proper maintenance of a methanol generator is key to ensuring its efficient and reliable operation, as well as extending its lifespan. Regular inspection of the fuel system helps prevent fuel leaks and ensures a smooth fuel supply. Checking and maintaining the engine oil keeps the engine well - lubricated, reducing wear and tear. Cleaning the air filter guarantees that the engine gets clean air, improving fuel efficiency and protecting the engine. Inspecting the electrical system ensures that the generator can start and run normally. By following these maintenance steps, you can keep your methanol generator in top condition, minimizing the risk of breakdowns and ensuring that it's ready to use when you need it. Investing time in maintenance not only saves you money on costly repairs but also ensures that your methanol generator provides consistent performance, meeting your power needs whenever required.