The MRO Tool Control with RFID Market is witnessing significant growth as the aviation and aerospace industries increasingly adopt Radio-Frequency Identification (RFID) technology to enhance maintenance, repair, and overhaul (MRO) operations. Research Intelo’s latest analysis indicates that the market is poised for steady expansion, driven by the need to improve tool tracking, reduce human error, and ensure operational safety in aircraft maintenance.

RFID-based tool control systems allow maintenance teams to accurately monitor inventory, track tool usage, and prevent misplaced or unaccounted tools. The resulting improvements in workflow efficiency, safety compliance, and audit readiness are prompting airlines, MRO service providers, and defense organizations to invest heavily in these solutions.

Moreover, advancements in IoT integration and real-time data analytics are transforming traditional MRO operations. RFID-enabled systems now provide actionable insights on tool lifecycle, usage frequency, and maintenance scheduling, enabling organizations to optimize resource allocation and reduce operational downtime.

Request a Sample Report:

https://researchintelo.com/request-sample/50964

Market Overview and Dynamics

The MRO Tool Control with RFID Market is primarily driven by the increasing complexity of modern aircraft maintenance operations. As aircraft fleets expand and technological sophistication rises, traditional manual tool tracking methods are proving insufficient, prompting the adoption of automated RFID systems.

Key Market Drivers

Enhanced Safety Compliance: Accurate tool tracking reduces the risk of foreign object damage (FOD) and ensures regulatory adherence.

Operational Efficiency: RFID-enabled systems streamline maintenance workflows, improving turnaround times and reducing labor costs.

Regulatory Mandates: Aviation authorities increasingly require robust tool accountability and documentation.

Furthermore, the market is supported by the growing adoption of digital MRO platforms that integrate RFID data with maintenance management systems. This integration allows real-time visibility of tool locations, inventory status, and usage metrics, providing significant operational advantages for large-scale maintenance facilities.

Restraints and Challenges

Despite strong growth prospects, the MRO Tool Control with RFID Market faces certain challenges. High initial investment costs for RFID hardware, software, and integration services may deter smaller operators from implementation.

Technical limitations, such as interference with metal surfaces and signal obstruction in dense tool storage environments, can affect tracking accuracy. Additionally, staff training and system adaptation are required to maximize benefits, which may extend deployment timelines.

However, technological advancements, including durable RFID tags, automated calibration, and user-friendly software interfaces, are addressing these limitations. As solutions become more cost-effective and reliable, adoption rates are expected to rise across commercial, defense, and industrial aviation sectors.

View Full Report:

https://researchintelo.com/report/mro-tool-control-with-rfid-market

Emerging Opportunities

Several opportunities are emerging that can accelerate market expansion. The integration of RFID with IoT and cloud platforms allows real-time monitoring of tool usage, predictive maintenance, and remote access to critical data. These capabilities enable MRO providers to enhance operational efficiency and reduce maintenance errors.

The expansion of defense aviation programs presents another growth opportunity. Military fleets require stringent tool tracking protocols for safety and operational readiness, making RFID tool control systems a strategic investment.

Moreover, increasing adoption of digital twin technology in MRO operations is expected to drive demand for RFID-enabled tools. Digital twins simulate aircraft maintenance processes and require precise data on tool availability and usage, reinforcing the need for advanced tool tracking systems.

Regional Insights

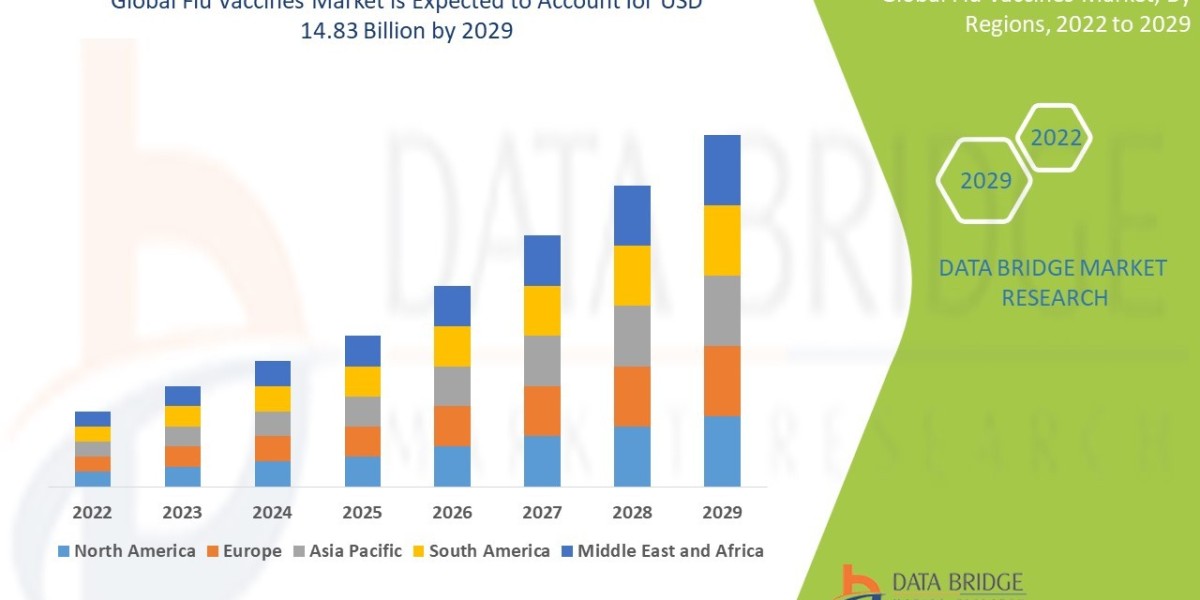

Regionally, North America dominates the MRO Tool Control with RFID Market, fueled by a high concentration of airlines, MRO service providers, and government regulatory initiatives promoting operational safety.

Europe follows, supported by stringent aviation regulations, the modernization of maintenance facilities, and the adoption of Industry 4.0 technologies in aerospace maintenance operations.

In Asia-Pacific, rapid growth in commercial aviation, the expansion of MRO infrastructure, and increased investment in defense programs are expected to boost market demand. Countries like China and India are emerging as key adopters of RFID-based tool control systems.

Meanwhile, Middle East and Africa are witnessing gradual adoption driven by fleet expansion, modernization initiatives, and increasing demand for operational safety compliance in commercial and defense aviation sectors.

Enquire Before Buying:

https://researchintelo.com/request-for-customization/50964

Future Outlook and Market Trends

The MRO Tool Control with RFID Market is expected to experience sustained growth as aviation operators increasingly seek automated solutions for efficient tool management. Emerging technologies, including AI-enabled predictive maintenance, advanced RFID sensors, and cloud-based management platforms, are expected to redefine MRO operations.

Key Market Trends

IoT and Cloud Integration: Facilitates real-time monitoring and data-driven decision-making.

AI-Enhanced Analytics: Enables predictive tool maintenance and workflow optimization.

Automation in Inventory Management: Reduces human errors and ensures regulatory compliance.

Adoption of Durable and Smart RFID Tags: Improves tracking accuracy even in challenging environments.

Furthermore, the adoption of green aviation practices and efficient resource management will drive investment in digital MRO solutions, reinforcing the strategic role of RFID tool control in reducing operational risks and costs.

Market Forecast and Strategic Insights

According to Research Intelo, the global MRO Tool Control with RFID Market is projected to expand steadily over the next decade. Increasing airline fleets, growing complexity in maintenance operations, and stringent regulatory compliance requirements are key drivers.

The market is also shaped by strategic collaborations between MRO providers and technology solution vendors. Such partnerships are accelerating the deployment of RFID-enabled tool control systems across commercial, defense, and business aviation sectors.

As aviation operators continue to prioritize operational efficiency, safety, and regulatory compliance, the demand for advanced tool control solutions is expected to rise, positioning the market for long-term growth and innovation.

Check Out the Report:

https://researchintelo.com/checkout/50964

Conclusion

In conclusion, the MRO Tool Control with RFID Market is poised for strong growth, driven by the aviation sector’s focus on operational efficiency, safety compliance, and digital transformation. The adoption of RFID-based tool tracking solutions enables real-time inventory management, reduces human error, and enhances maintenance workflow efficiency.

Research Intelo’s comprehensive market study highlights critical trends, opportunities, and challenges, offering valuable insights for stakeholders looking to invest in or expand within the RFID-enabled MRO solutions market. With continued technological innovation and regulatory emphasis on safety, RFID tool control systems are expected to become a standard in aviation maintenance worldwide.