Selecting the right horizontal machining center (HMC) is a critical decision that can significantly impact your manufacturing efficiency and product quality. With the plethora of options available in the market, understanding the essential features and benefits of HMCs can guide you in making an informed choice that aligns with your operational requirements.

Understanding Horizontal Machining Centers

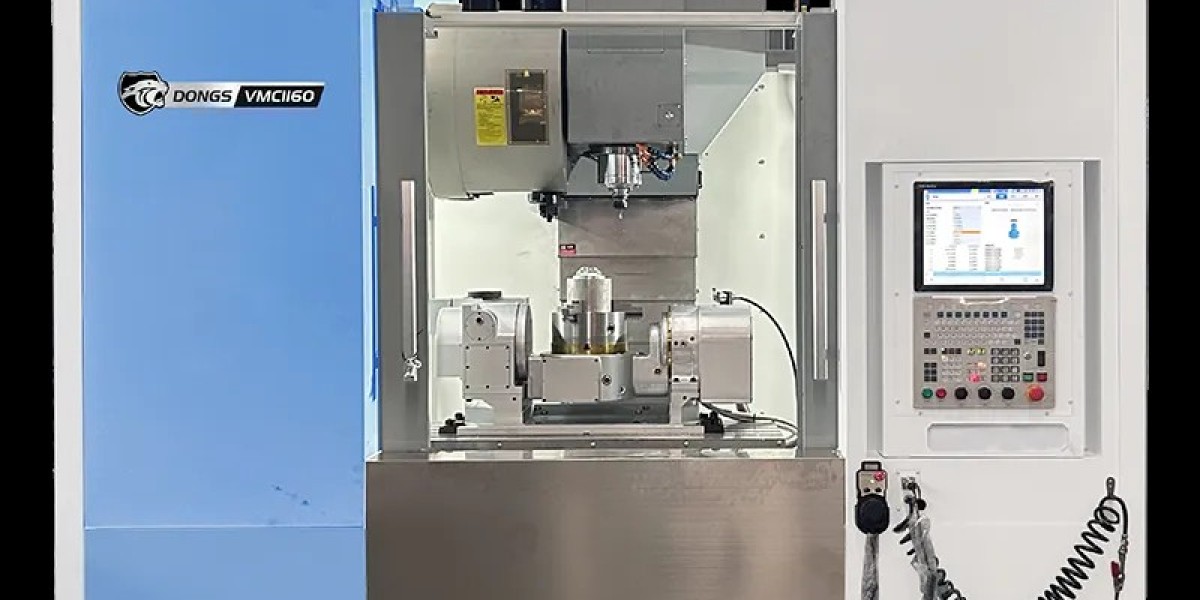

Horizontal machining centers are designed for high-speed, high-precision machining of various materials. Unlike vertical machining centers, HMCs have a horizontal spindle orientation which allows for better chip removal and improved tool access. This design is particularly advantageous for complex parts that require multiple operations, thereby reducing cycle times and increasing productivity.

Key Features to Consider

When choosing a horizontal machining center, consider the following key features:

1. Spindle Power and Speed: The spindle power and speed determine the types of materials you can machine effectively. Higher spindle speeds allow for faster cutting, while adequate power ensures that the machine can handle tougher materials without stalling.

2. Tool Capacity: An HMC with a larger tool capacity allows for more tools to be loaded, reducing the need for frequent tool changes and minimizing downtime. Look for models that offer automatic tool changers for increased efficiency.

3. Work Envelope Size: The size of the work envelope should match the dimensions of the components you intend to manufacture. A larger work envelope provides flexibility for larger parts and complex setups.

4. Control System: Modern HMCs come equipped with advanced control systems that enhance usability and precision. User-friendly interfaces and programmable features can significantly reduce the learning curve and improve operational efficiency.

Evaluating Your Production Needs

Before making a purchase, assess your production needs comprehensively. Consider factors such as production volume, part complexity, and material types. If your operations involve high-volume production of similar parts, investing in a high-speed HMC may yield significant returns. Conversely, if you require versatility for low-volume, complex parts, a more adaptable machine could be beneficial.

Budget Considerations

Budgeting is a crucial aspect of selecting the right horizontal machining center. While it may be tempting to opt for the least expensive option, consider the long-term costs associated with maintenance, tooling, and potential downtime. Investing in a reliable, high-quality HMC may be more cost-effective in the long run, as it can enhance productivity and reduce operational issues.

Conclusion

Choosing the right horizontal machining center is a multifaceted decision that requires careful consideration of your specific manufacturing needs. By understanding the key features, evaluating your production requirements, and considering your budget, you can select an HMC that will enhance your operational efficiency and product quality. The right investment in a horizontal machining center can lead to significant improvements in your manufacturing processes, ultimately driving your business success.