A Ferrite Magnets Factory plays a key role in supplying magnetic materials for various industries, including electronics, automotive, household appliances, and renewable energy. Ferrite magnets are widely used because of their resistance to corrosion, thermal stability, and reliable magnetic properties. By producing a consistent and versatile product, a Ferrite Magnets Factory supports manufacturers who require precise and durable magnetic components for their equipment and applications.

The production process in a Ferrite Magnets Factory involves multiple stages, including raw material preparation, mixing, pressing, sintering, and magnetization. High-quality raw materials, such as iron oxide and barium or strontium carbonate, are combined to form ferrite powder. This powder is then shaped into the required size and form. A well-managed Ferrite Magnets Factory ensures that each magnet meets specific strength, size, and tolerance standards suitable for various industrial uses.

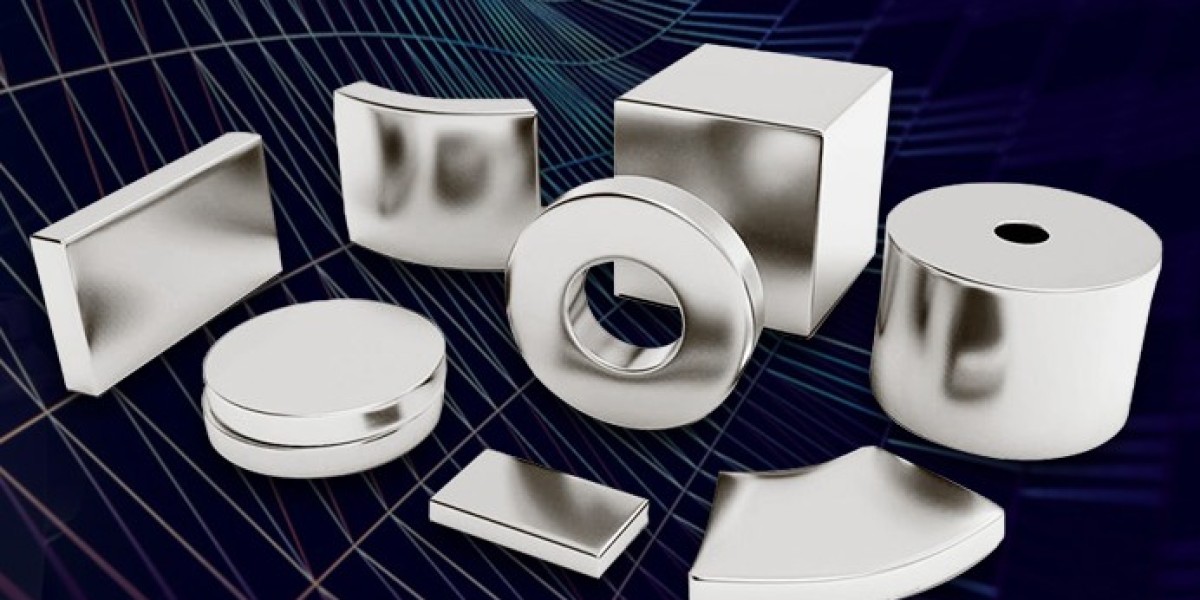

Customization is a significant advantage of working with a Ferrite Magnets Factory. Different industries may require magnets in diverse shapes, such as discs, rings, blocks, or arc segments. Some applications also demand specific magnetic strength, coercivity, or temperature resistance. A reliable Ferrite Magnets Factory can adjust production methods, material composition, and magnetization processes to meet these requirements, allowing clients to receive components tailored to their applications.

Durability is another feature that a Ferrite Magnets Factory emphasizes. Ferrite magnets are inherently resistant to corrosion and maintain their magnetic performance over time. The factory often conducts quality inspections to check for cracking, chipping, or uneven magnetization, ensuring that each product performs consistently. Reliable quality control reduces the risk of failure in critical systems, whether in motors, generators, or electronic devices.

Efficiency in production is a consideration for both the factory and its clients. A Ferrite Magnets Factory often implements advanced sintering and pressing techniques to maintain uniform density and magnetic properties across batches. By controlling these processes carefully, the factory ensures consistent performance, which benefits industries relying on precise magnetic fields, such as electric motors or magnetic separators.

Environmental and safety considerations are increasingly important in a Ferrite Magnets Factory. The factory may use eco-friendly processing methods and manage waste materials responsibly. Proper handling of ferrite powders and sintered magnets ensures that employees work in a safe environment while maintaining product quality.

A Ferrite Magnets Factory also offers technical support to clients. Engineers can provide guidance on selecting the right magnet type, shape, and grade for specific applications. This support helps prevent mismatches, reduces trial-and-error during assembly, and enhances overall efficiency. Clear communication between the factory and clients is key to delivering products that meet operational expectations.

Another advantage of sourcing from a Ferrite Magnets Factory is the availability of both standard and specialized magnets. While standard shapes suit many common applications, custom-designed magnets are important for motors, sensors, and renewable energy devices. The ability to provide both options ensures the factory can meet diverse industrial needs.

A Ferrite Magnets Factory is essential for producing reliable and versatile magnets used across multiple industries. Through careful material selection, precise production, and technical support, the factory supplies magnets that meet specific performance and durability requirements. Companies that work with a Ferrite Magnets Factory benefit from consistent quality, customization options, and technical guidance, enabling smooth integration of magnetic components into their products.