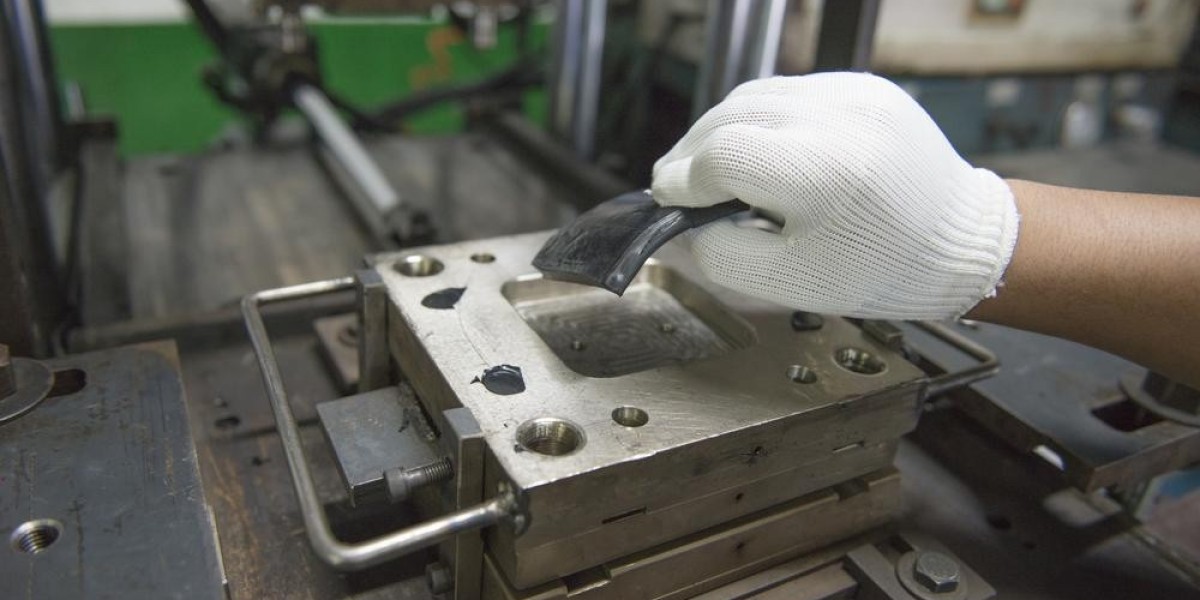

Deciding to buy compression molding is a strategic choice for manufacturers seeking high-quality and reliable components. Industries such as automotive, aerospace, electronics, and medical devices rely on companies that buy compression molding to produce parts with consistent performance and regulatory compliance.

Advantages of Buying Compression Molding

When manufacturers buy compression molding, they acquire components with excellent mechanical strength, dimensional accuracy, and thermal resistance. Companies that buy compression molding benefit from a manufacturing process that ensures reproducibility, reliability, and efficiency.

Material Considerations

Selecting the correct material is critical when you buy compression molding. Common options include thermosets, BMC, SMC, and fiber-reinforced composites. By choosing suitable materials when you buy compression molding, manufacturers ensure that components withstand mechanical stress, temperature extremes, and chemical exposure.

Applications Across Industries

Companies that buy compression molding often apply it to automotive panels, aerospace structural parts, electronic housings, and medical devices. The flexibility of compression molding ensures that organizations that buy compression molding receive components tailored to industry-specific performance and compliance standards.

Selecting a Reliable Supplier

When you buy compression molding, partnering with a trusted supplier is essential. Providers with advanced machinery, precision molds, and verified quality systems ensure that when you buy compression molding, components are produced consistently and efficiently.

Quality Assurance and Compliance

Manufacturers who buy compression molding must ensure that suppliers maintain rigorous quality control procedures. Inspections, mechanical testing, and certifications guarantee that when you buy compression molding, your components meet performance, durability, and compliance expectations.

Sustainability Considerations

Sustainability is an increasingly important factor when you buy compression molding. Suppliers who employ energy-efficient machinery and recyclable materials allow companies that buy compression molding to achieve eco-friendly production practices without compromising component quality.

Conclusion

To successfully buy compression molding, manufacturers should evaluate materials, supplier expertise, quality assurance, and sustainability practices. Companies that buy compression molding secure precise, durable, and high-performance components that support efficient and compliant industrial manufacturing.