Customized Logo Printing on Plastic Packaging: Hot Stamping & Screen Printing

When it comes to adding a customized logo on plastic packaging—such as PET beverage bottles, PP cosmetic containers, or pharmaceutical jars—hot stamping and automatic screen printing are two standout choices. Hot stamping creates a sleek, metallic finish that instantly elevates brand luxury, making it perfect for high-end cosmetics or premium beverage lines. It adheres firmly to materials like PE, PS, and PVC, ensuring the logo stays intact even with frequent handling. Automatic screen printing, on the other hand, offers vibrant, long-lasting colors and precise detail, ideal for complex logos or multi-color designs. This method works seamlessly for bulk orders, whether you’re producing 250 units or large-scale batches, and maintains consistency across every piece. Both techniques prioritize durability, so your brand logo remains crisp and professional, reinforcing recognition with every customer interaction.

Logo Customization on Glass Packaging: Precision & Aesthetics

Glass packaging—like olive oil dispensers or perfume spray bottles—deserves a logo application that matches its elegance. For glass containers, techniques like UV printing and laser engraving deliver exceptional results. UV printing uses quick-drying inks that bond tightly to glass surfaces, offering bold, fade-resistant logos that stand out without compromising the material’s clarity. It’s versatile enough for intricate designs, from minimalist brand names to detailed emblems, and works well for both small-batch and mass-produced items. Laser engraving, on the other hand, creates a subtle, etched effect that exudes sophistication—perfect for luxury skincare or gourmet food packaging. This method is eco-friendly, as it requires no inks or chemicals, and the engraved logo won’t peel or wear off over time. Whether you’re aiming for a modern look or timeless charm, these techniques ensure your customized logo enhances the glass packaging’s appeal while staying true to your brand.

Low MOQ Logo Customization: Perfect for Small Businesses & Startups

One of the biggest challenges for small businesses and startups is finding customized logo packaging solutions that don’t require exorbitant minimum order quantities (MOQ). The good news is that flexible options exist to cater to smaller batches, starting from as low as 250 pieces. This accessibility allows emerging brands to invest in branded packaging without overextending their budgets. Whether you need logo-printed travel-sized cosmetic spray bottles or small-batch pharmaceutical containers, manufacturers offer tailored services that prioritize quality without sacrificing customization. These solutions include digital printing for quick turnarounds and cost-effective small runs, as well as pre-stocked packaging options that can be personalized with your logo on demand. With low MOQ customization, even small brands can compete with larger competitors by presenting a cohesive, professional brand image through their packaging.

Ensuring Logo Compliance & Durability for Specialized Industries

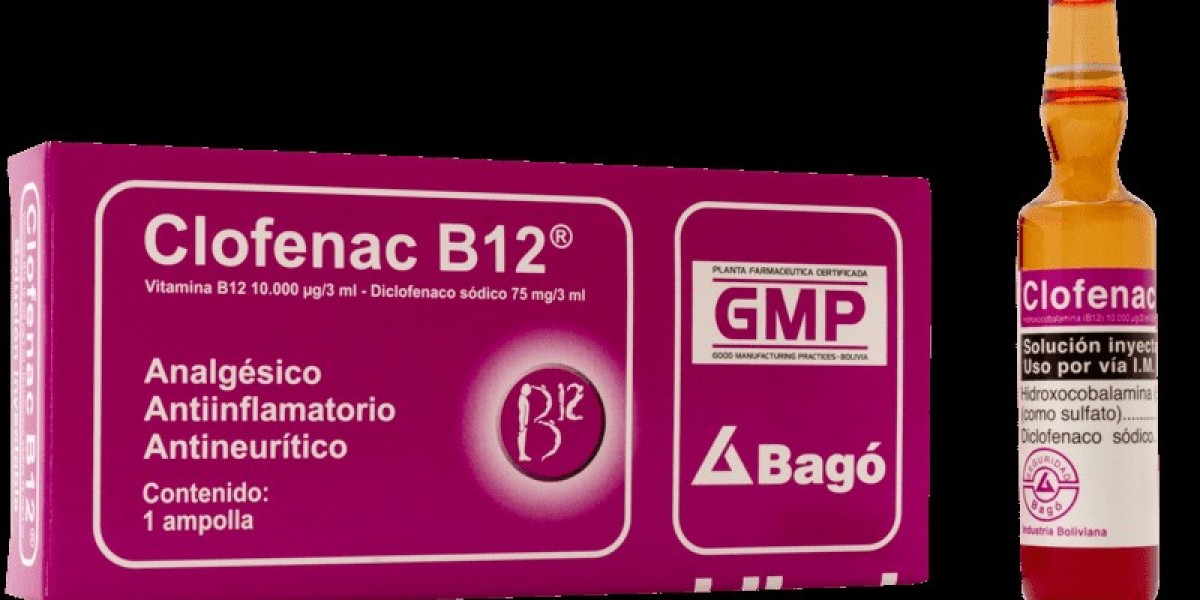

For industries like pharmaceuticals and cosmetics, adding a customized logo isn’t just about aesthetics—it’s about compliance and durability. Pharmaceutical packaging, such as child-proof pill bottles, requires logos that meet strict health and safety standards, with inks that are non-toxic and resistant to moisture or temperature changes. Cosmetic packaging, meanwhile, needs logos that can withstand exposure to oils, creams, and frequent use without fading or smudging. Reputable packaging providers adhere to certifications like ISO9001 and SGS, ensuring that logo printing processes meet industry-specific regulations. Additionally, using high-quality materials—such as food-grade PET or borosilicate glass—paired with professional application methods guarantees that your logo remains legible and intact throughout the product’s lifecycle. This attention to compliance and durability not only protects your brand reputation but also builds trust with customers who prioritize safety and quality.

Conclusion

Adding a customized logo on packaging is a powerful way to strengthen brand identity, boost recognition, and connect with customers—whether you’re in pharmaceuticals, cosmetics, beverages, or any other industry. From hot stamping on plastic bottles to laser engraving on glass containers, the right technique depends on your packaging material, brand aesthetic, and order size. Low MOQ options make customization accessible to businesses of all scales, while compliance-focused methods ensure your logo meets industry standards without compromising quality. By investing in professional logo printing and customization, you’re not just enhancing your packaging—you’re creating a memorable brand experience that resonates with customers long after their purchase. Choose solutions that align with your brand values, and let your customized logo tell your brand’s story through every package.