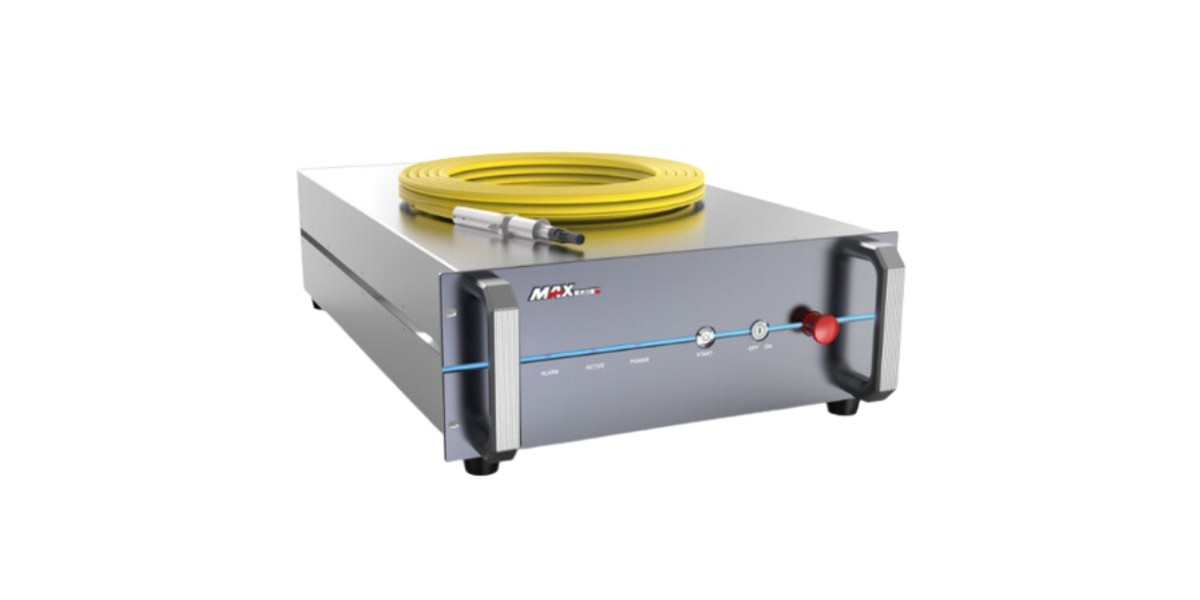

In recent years, the manufacturing landscape has undergone a significant transformation, driven by advancements in technology and the need for greater efficiency. Among the innovations reshaping this industry, fiber laser sources have emerged as a pivotal element. Their ability to deliver high precision, speed, and flexibility has made them indispensable in various manufacturing applications. This article delves into the role of fiber laser sources in modern manufacturing, exploring their advantages and the impact they have on production processes.

Precision and Efficiency

Fiber laser sources are renowned for their exceptional precision. The focused beam of light produced by these lasers allows for intricate cutting, engraving, and welding tasks that were previously challenging with traditional methods. This level of accuracy not only reduces material waste but also enhances the quality of the final product. Moreover, the speed at which fiber lasers operate significantly boosts manufacturing efficiency. With rapid processing times, companies can meet tight production deadlines without compromising on quality. This efficiency translates to cost savings and improved profitability for manufacturers.

Versatility Across Industries

One of the standout features of fiber laser sources is their versatility. They can be employed in a wide range of applications across various industries, including automotive, aerospace, electronics, and medical device manufacturing. Whether it's cutting metal sheets, marking components, or welding intricate parts, fiber lasers adapt seamlessly to different materials and thicknesses. This adaptability makes them a valuable asset for manufacturers looking to diversify their product offerings and stay competitive in an ever-evolving market.

Lower Operational Costs

When considering manufacturing technologies, operational costs are a crucial factor. Fiber laser sources have proven to be cost-effective in the long run. Their energy efficiency means lower electricity consumption compared to other laser types. Additionally, the reduced need for maintenance due to the solid-state nature of fiber lasers further minimizes operational expenses. As manufacturers strive to optimize their budgets, investing in fiber laser technology becomes an attractive option that promises both immediate and long-term financial benefits.

Enhanced Safety Features

Safety is paramount in any manufacturing environment. Fiber laser sources contribute to a safer workplace by minimizing the risks associated with traditional laser systems. Their compact design reduces the need for extensive safety measures, while the lower levels of hazardous emissions make them a more environmentally friendly choice. By integrating fiber laser sources into their operations, manufacturers not only improve safety but also demonstrate a commitment to sustainable practices, appealing to environmentally conscious consumers.

Future Trends in Fiber Laser Technology

As technology continues to advance, the future of fiber laser sources looks promising. Innovations in beam quality, power output, and automation are set to enhance their capabilities further. The integration of artificial intelligence and machine learning into fiber laser systems will enable smarter manufacturing processes, allowing for real-time adjustments and optimizations. Manufacturers who embrace these trends will be well-positioned to lead in their respective industries, leveraging the full potential of fiber laser technology.

In conclusion, fiber laser sources are revolutionizing modern manufacturing by offering unparalleled precision, efficiency, and versatility. As industries evolve and the demand for high-quality products increases, the adoption of fiber laser technology will continue to grow. Manufacturers that invest in this cutting-edge solution will not only enhance their operational capabilities but also secure a competitive edge in the marketplace. The role of fiber laser sources in shaping the future of manufacturing cannot be overstated, making them an essential component of any forward-thinking production strategy.