Ordering electrical components for Tadano cranes might seem like a routine task, but it's fraught with potential pitfalls. The wrong part can lead to significant delays and safety issues. Tadano parts are engineered with precision, and even minor errors can have a big impact. Here are five common mistakes and how to avoid them to ensure you get the right Tadano parts quickly and safely.

1) The Problem with Vague Descriptions

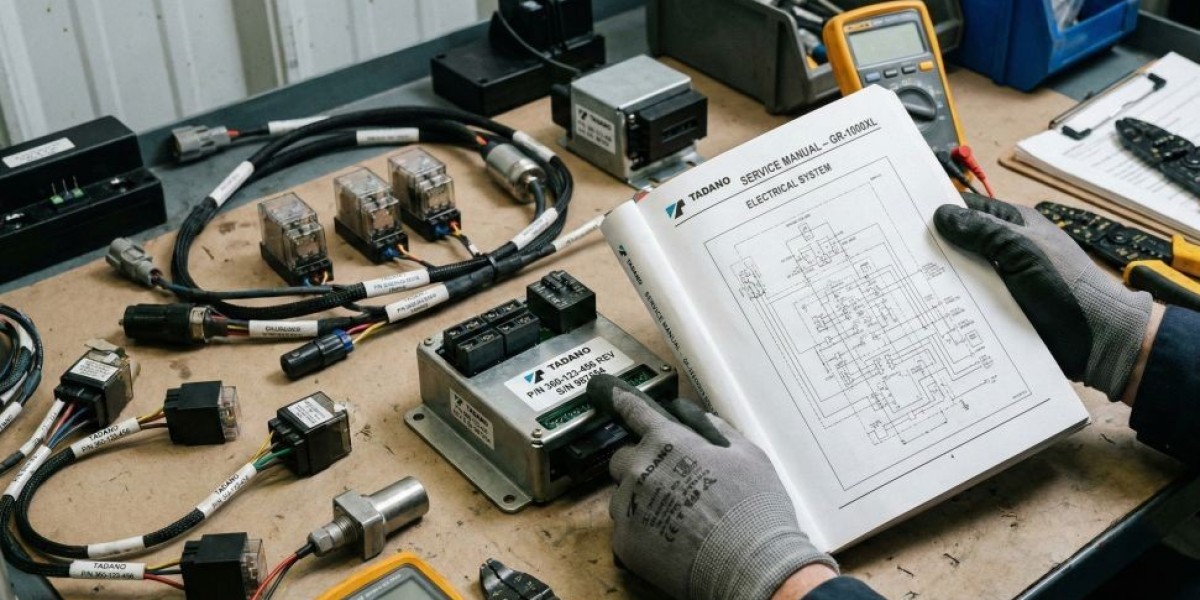

It's common for people to describe a part by its appearance, such as "that black sensor" or "the control board for the cab." However, this approach rarely works. Tadano parts are identified by specific part numbers and revision codes for a reason. Two parts may look identical but have different firmware or connector layouts. Always start with the exact part number from the manual or parts catalog. If you can't find the number, provide the crane model and full serial number to your supplier. Sending clear photos from multiple angles can also help. Verifying the part upfront is inexpensive compared to the cost of replacing a wrong electrical module later.

2) The Importance of Serial Ranges and Revisions

Tadano continuously updates its components. A control unit from a 2012 model might not fit a 2018 model, even if the part number appears similar. Revisions, batch updates, and superseded part numbers are common in electrical assemblies. Always check the machine's serial range against the Tadano parts catalog. If a part number lists supersessions, confirm which revision matches your crane. Providing the serial number and any visible revision markings to your supplier can reduce returns and prevent electrical incompatibility that could lead to downtime or diagnostic errors.

3) The Risks of "Close Enough" Alternatives

Electrical components are sensitive, and using third-party or aftermarket modules can introduce subtle faults. A non-genuine sensor might send slightly different voltage signatures, or a cheap connector could corrode faster. For critical systems, "close enough" is not acceptable. When safety and reliability are paramount, insist on genuine Tadano parts. Work with a reputable supplier who can provide proof of authenticity, including part origin, batch numbers, and traceable documentation. If you must use an alternate, thoroughly test it in a safe setting and document the results.

4) The Reality of Lead Times

Many people assume that electrical parts are easy to source because they are small. However, specialized Tadano parts, custom controllers, or modules with approved firmware can have longer lead times. Waiting until a failure occurs can result in weeks of downtime. Plan ahead by creating a spares list for the most failure-prone electrical items. Discuss realistic delivery windows with your supplier. For critical cranes, consider stocking spare controllers or sensors. The initial inventory cost is usually much less than the cost of downtime.

5) The Necessity of Documentation

Replacing a control module might seem like a straightforward task, but later issues can arise if you don't document the change. Diagnostics might show odd errors, or you might forget the firmware version of the new module. Record every electrical part change, including the Tadano parts part number, serial, revision, firmware version, installer, and installation date. Keep photos of serial plates and connector orientations. Sharing this documentation with your supplier and maintenance team can save time if you need support, a warranty claim, or a rollback to previous firmware.

Practical Steps to Avoid These Mistakes

Start by treating electrical orders as critical safety items. Use the catalog to extract exact part numbers and match them to the model and serial range before ordering. Provide your supplier with full machine data and clear photos. Confirm lead times and request traceability documents. If you keep spares, rotate them into regular service to ensure they remain current and tested. Train technicians to read revision stamps and firmware labels, and make it standard practice to record the installer's name and firmware version when fitting a part. This simple habit can prevent many follow-up problems.

Why Your Choice of Crane Parts Supplier Matters

Many mistakes occur because teams work with the wrong supplier. A good crane parts supplier understands Tadano parts nomenclature and can quickly decode revisions. They will also warn you about long lead times, suggest legitimate alternates when appropriate, and provide traceability documentation. If your supplier hesitates when asked for authentic Tadano parts or can't confirm serial-range fitment, it's time to find a new partner. Your supplier should reduce risk, not add uncertainty.

Real-World Example

A yard I worked with replaced what seemed to be a matching joystick module. The part fit mechanically, but the crane intermittently dropped communication during certain maneuvers. The issue was traced back to a non-genuine part with a slightly different grounding scheme. The fix was an OEM Tadano parts module from a trusted supplier, but the delay and lost shifts cost far more than the part itself.

Final Thoughts

Ordering Tadano parts for electrical systems requires attention to detail: part numbers, serial ranges, authenticity, lead times, and documentation. Treat these orders as you would any critical safety task. Work with a trusted crane parts supplier, confirm fitment, and keep records. By doing so, you reduce downtime, avoid surprises, and ensure that crews and machines operate efficiently and safely.