Sulfur Hexafluoride (SF6) is globally recognized as an essential insulating medium in high-voltage electrical infrastructure. However, the substance is also one of the world's most potent known greenhouse gases, listed in the Kyoto Protocol. This dual nature makes advanced sf6 gas handling and strict control over operational emissions absolutely crucial. Improper management or leakage poses a double threat: immediate operational failure due to gas contamination, and long-term environmental liability due to its high Global Warming Potential (GWP), which is 23,500 times that of CO2.

One of the most critical challenges in effective sf6 gas handling is the control of moisture contamination. Moisture, or micro-water, can enter SF6 gas through various pathways: residual moisture from the gas production process, contamination during equipment maintenance and air supplementation (especially if vacuuming time is insufficient), or penetration through weak equipment seals over time. The V-shaped structure of water molecules allows them to penetrate seals more readily than the larger, regular octahedral SF6 molecules, driven by external atmospheric moisture pressure. The presence of moisture is detrimental, as it dramatically lowers the dielectric strength of the gas, compromising the insulation level necessary for safe operation. Furthermore, when moisture is present and the gas is exposed to high-power arcs or corona discharge, it reacts with the decomposing SF6 byproducts, accelerating the formation of highly toxic and corrosive substances like hydrogen fluoride (HF) and sulfur dioxide (SO2). These toxic compounds not only present a serious health risk to personnel but also physically corrode internal equipment components, leading to premature failure.

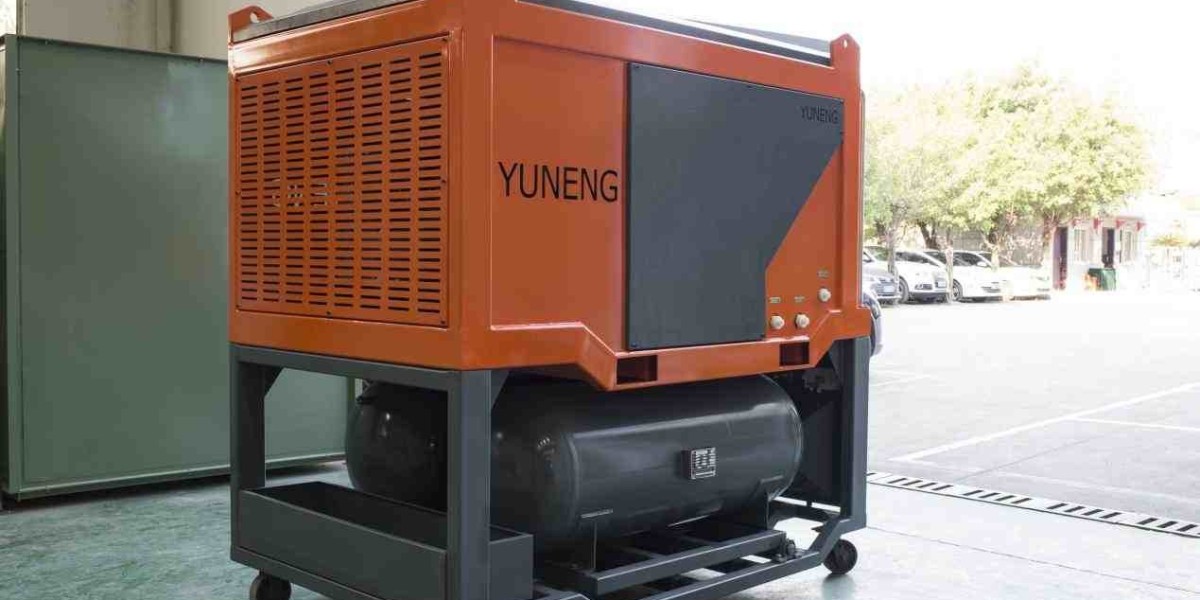

To effectively control these risks, utilities must adopt a multi-pronged strategy, the cornerstone of which is specialized sf6 gas recovery equipment. Beyond regular checks of sealing parts and timely replacement of saturated adsorbents, the most effective tool is the process of purification and drying performed by recovery machines. These machines are designed to pull the contaminated gas from the electrical apparatus and put it through a rigorous cycle of drying and purification. Modern SF6 recovery equipment, such as that developed by YUNENG, integrates powerful vacuum systems and advanced filtration technology (high-efficiency adsorbents coupled with electric heating regeneration) to actively strip moisture and harmful solid or oil contaminants from the gas.

The capability of the sf6 gas recovery machine to process the gas ensures that the gas reintroduced into the electrical equipment meets necessary dryness and purity specifications, thereby restoring its insulating properties and minimizing the risk of corrosive byproduct formation. By meticulously controlling micro-water and decomposition products through dedicated sf6 gas handling units, operators not only preserve the environment by preventing gas release but also safeguard valuable electrical assets against internal corrosion and maintain the operational safety and reliability of the entire power system.