A team at a Solenoid Valve Factory may spend significant time understanding the expectations placed on a Sanitary Ware Solenoid Valve, as these components support automated water control in homes and public spaces. Their ability to manage switching cycles reliably makes them essential to everyday sanitary installations.

Many valve designs begin with an evaluation of expected flow rates. Sanitary fixtures often require moderate flow, avoiding sudden changes that could disrupt the user experience. Engineers shape internal channels to maintain a stable pattern even when the water supply varies slightly.

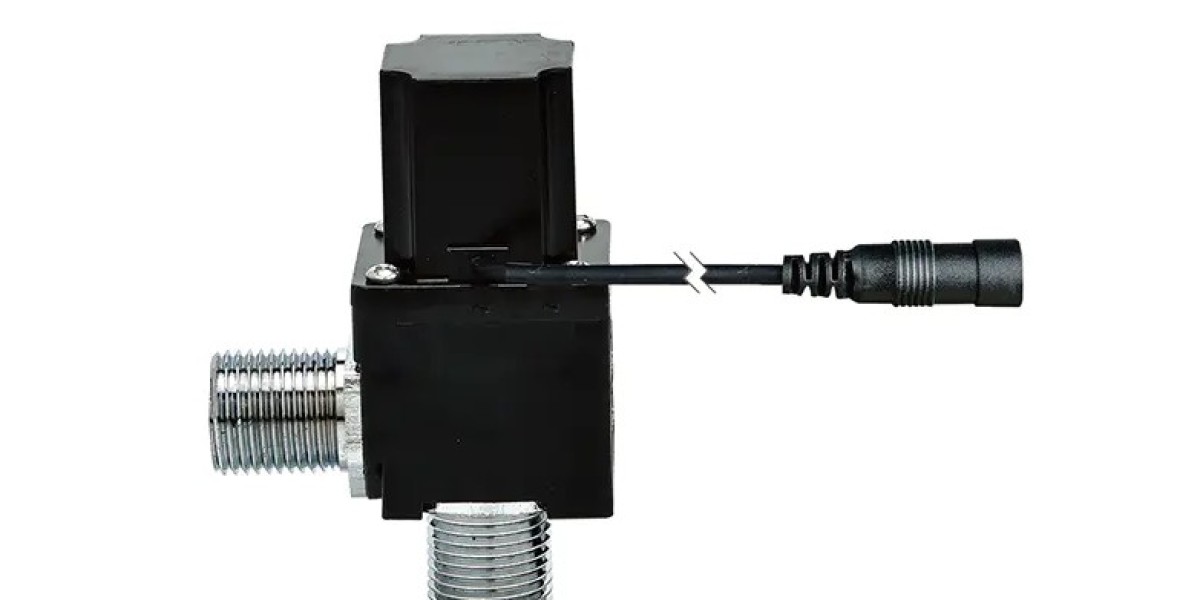

Sanitary valves must also fit into compact mounting zones. Tight installation spaces behind panels or under basins require designs with minimal bulk. Factories coordinate machining, coil assembly, and housing development to maintain appropriate size and clearances.

Installers tend to prefer valves that support convenient wiring. Factory teams respond by offering multiple voltage options, connector types, and cable protection structures. These decisions make the component adaptable across different building layouts.

The durability of internal seals impacts long-term function. Water quality, minerals, and cleaning chemicals interact with the valve daily. Factories assess sealing materials to ensure stable operation without adding unnecessary complexity. Regular quality checks help confirm each batch meets requirements.

Sound control continues to be an important design topic. Users appreciate fixtures that operate quietly, especially in bedrooms, hotel rooms, or office environments. Engineers explore spring tension, coil responsiveness, and channel geometry to reduce abrupt movement.

Maintenance teams benefit from valves that include accessible components. A removable strainer or cover lets them clear deposits after extended use. This keeps the entire sanitary fixture functioning smoothly and reduces service time.

The coordination between mechanical design and electrical response defines the valve’s behavior. Both parts must work together seamlessly for a faucet or flush system to activate correctly. When the factory refines these elements, the resulting sanitary valve performs more consistently.

Buildings adopting automated sanitary systems rely heavily on components produced by a Solenoid Valve Factory, and the design of a Sanitary Ware Solenoid Valve shapes how water is distributed and controlled across daily routines.