In the world of high-precision manufacturing, the quest for dimensional stability, superior surface finish, and cost-effective production is relentless. While many materials are available for creating jigs, fixtures, and molds, aluminium cast plate has carved out a critical niche, offering a unique set of properties that bridge the gap between soft wrought alloys and hard, expensive tool steels. For engineers designing molds for the automotive, aerospace, or plastics industries, understanding the distinct advantages of a specialized aluminium cast plate, such as the 5A83 alloy, is essential for achieving precision and efficiency.

The primary challenge in machining large components is controlling distortion and maintaining tight tolerances. Traditional wrought aluminum plates, like some grades of aluminium tread plate used for structural applications, have a directional grain structure from the rolling process. This can lead to unpredictable stress relief and deformation during aggressive machining. In contrast, a precision aluminium cast plate is produced through a vertical casting process that results in a fine, homogeneous, and isotropic grain structure. This means its mechanical properties are uniform in all directions. As the link describes, CHAL's 5A83 plate is also stress-relieved, ensuring "extraordinarily dense, dimension stable" characteristics with "minimal or no distortion even after extensive machining operations." This dimensional stability is the cornerstone of its value, allowing for the creation of complex, high-tolerance tools that remain accurate over time.

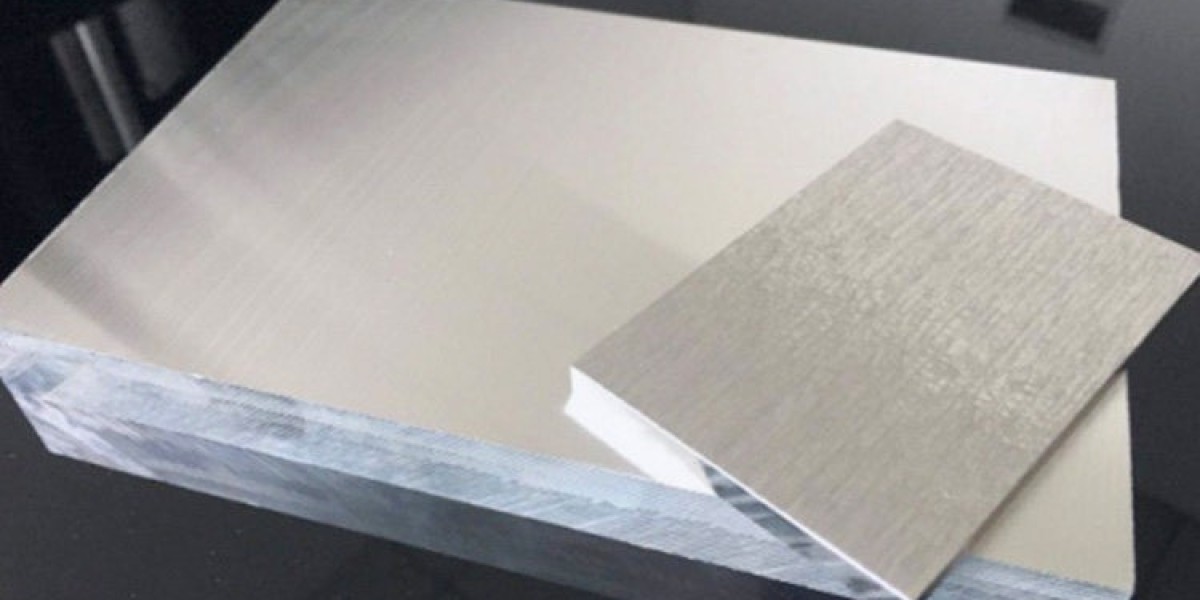

The advantages of using a cast aluminum plate become starkly clear when compared to alternatives. Compared to tool steel, aluminum cast plate is significantly lighter, easier to machine (reducing tool wear and machining time), and offers better thermal conductivity, which is crucial for cooling cycles in plastic injection molding. Its cost-effectiveness is a major driver. While a aluminium tread plate might be chosen for its surface durability in walkways, the aluminium cast plate is chosen for its internal integrity for machining. The provided text notes that "wrought alloys are too soft and gummy," which can lead to poor surface finishes and tool clogging. The 5A83 alloy, with a hardness of 70 HB, offers an ideal balance, being soft enough for high-speed machining yet strong enough for functional tooling applications.

Applications for these plates are found in high-tech industries. They are ideal for machining fixtures, drill jigs, injection molds for high-temperature plastics, and components in the semiconductor and pharmaceutical sectors. The material's excellent weldability and good anodic oxidation properties add to its versatility for repair and surface enhancement. Suppliers provide these plates with precision-milled surfaces (surface roughness Ra < 0.4µm), protected with PVC film, and with exceptional flatness (as tight as ≤0.12mm for thicker plates). This level of readiness out of the box further reduces preparation time and cost. In summary, the aluminium cast plate represents a sophisticated material solution specifically engineered to meet the rigorous demands of modern precision manufacturing, offering a compelling combination of stability, machinability, and overall value that outperforms both conventional aluminum plates and heavier steel options.