Incoming Quality Control for Raw Materials: The Starting Point for Quality

The most important component of any product is the materials that go into it and having strict control of what materials you accept is your first line of defense for having a high overall quality product. Because of this, Kanas does what we call a “double-inspection” standard. The first part of this “double-inspection” is only working with suppliers that have ISO certifications, a long-term collaborative history, and detailed quality inspection reports and certificates of conformity. The second part of the “double inspection” is having a 100% inspection of certain key materials once they arrive. Inspections of materials such as motors, impellers, and casing inspects for a variety of traits, including: composition standards which can be verified through spectrochemical analysis, dimensional size using coordinate measuring machines, and various efficiency metrics of the motor and balance of the impeller. The materials that we do not accept, never make it to the production line. Because of this, we maintain high quality materials through strict incoming inspections and a resultant high quality production process.

Quality Control Standards in Each Production Process

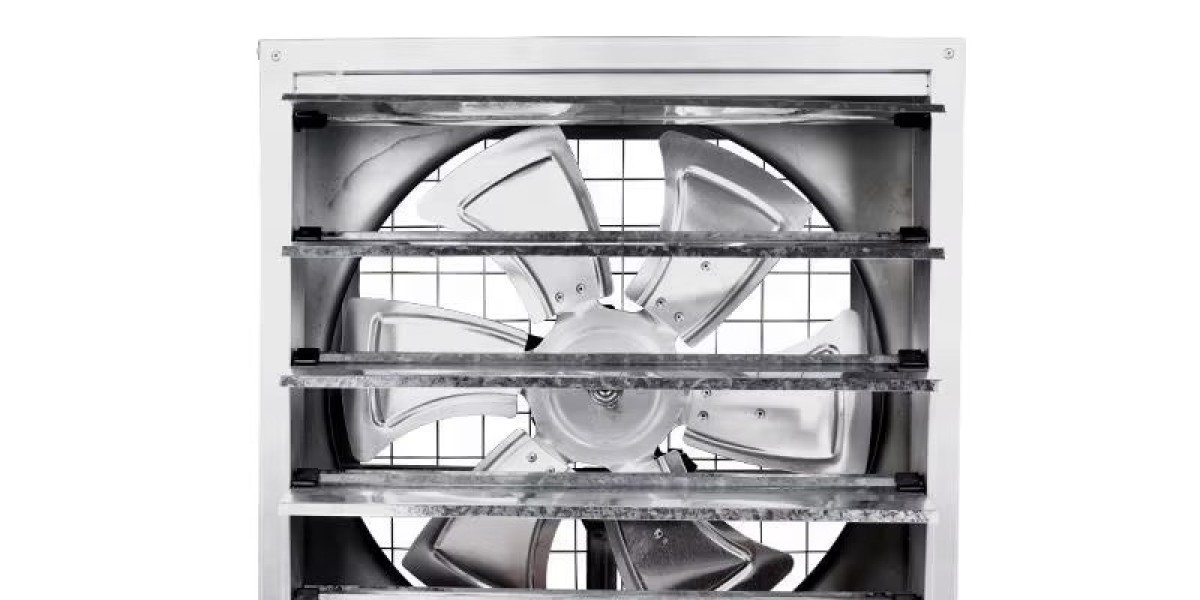

Quality is highly variable in the production process. Kanas has set detailed operating standards and inspection items for each production process. For the stamping and forming of casings, the dimensional tolerance is controlled and flattened, and each batch is sampled for strength testing. For the assembly of the impeller, there is a dynamic balance test. Each impeller must pass a balance test to avoid operational vibration at a residual unbalance of unbalance of ≤0.5g·mm/kg. For the motor winding, there are separate tests on the winding resistance, insulation resistance, and withstand voltage performance to avoid electrical failures. Moreover, each production line is staffed with real-time quality control inspectors, and any non-conforming product is marked for tracking. Such a standard of process control surrounding quality keeps one in the scope of defected items and reduces the chances of unqualified products at the ending line to a minimum.

Final Product Verification Performance Testing Standards: The Last Verification

To make sure that the final exhaust fans pass all the predetermined requirements, Kanas does extensive pre-delivery performance testing of all products, which is the final guarantee for the 98% of all products testing passing the requirements. The five testing areas include: first is air performance testing (flow rate, pressure of air served) using professional air testing tunnel, to ensure that are specifications are met; second is electrical safety testing (leakage current, insulation resistance, ground continuity) under IEC 60335 and national safety standards; third is proper noise control, which is done within the designed range of the noise under an anechoic chamber; fourth is verifying the long-term operational stability of the unit, which is done through the durability testing of 72 hours of nonstop operation; and fifth: The final quality control is done for the inspection of the visible parts and the quality of assembly testing, which includes searching for quality control defects like scratches, loose screws, and improper assembly. Only the products that pass all five areas are sealed and are eligible to go out of the factory.

Kanas Success Rate and Certification in Quality Management and Systematic Assurance

Due to the high level of quality management systems in Kuvas, the company boasts a high level of success. Kanas possesses ISO 9001:2015 quality management system certification, which provides comprehensive management of the quality control systems in R&D, purchasing, manufacturing, sales and aftermarket services. Under this system, quality records must be detailed and maintained for every manufacturing lot, including raw material inspection test reports, production process inspection reports and fully completed product test reports, allowing for quality issue traceability. Kanas also retains quality and safety certifications for its exhaust fans as required by other countries and jurisdictions (CE, UL, ROHS). Quality management systems are required to be continually improved by internal reviews and external reviews by certification bodies. Systematic certification assurance explains the high level of quality control.

Continuous Improvement Standards: Sustaining High Quality

Having a 98% pass rate is not a destination it's a process. For this reason, Kanas continues to improve to achieve more quality. A defect quality process is looked at. For the 2% unqualified defected products, we determine the root cause; is it the raw materials, processes, or testing hands? Improvement measures are what we are defining. Kanas also modified upstream electronic testing. Equipment to improve defect processes for testing products to the market are also modified. User feedback is also incorporated. For example, a user feedback report for a defected product mainly noise, the company improved impeller configurations and balance standards for testing. Quality becomes more informed for the customer demands and rapid improvements in technology. Exhaust fans remain high quality in the market injuries.