Consider the Accuracy and Pressure Logistics of Your Automation.

Industrial automation of high accuracy requires specific vacuum pressure and stability in the system, and so it is essential to establish requirements first. A CNC vacuum pump from Jinan Golden Bridge is designed to be able to control pressure with the utmost precision, and can be modified to fit the various levels of automation needed, from the assembling of microchips to the machining of molds at a high level of precision. Think of things like the vacuum level needed, how much pressure the system is able to take without failure, and whether the system needs to be operational at all times. A CNC vacuum pump that meets your precision benchmarks will guarantee the constant holding of the workpieces and operational accuracy. (Defects will be caused by a lack of adequate suction, pressure instability, and inadequate processing speed on the workpieces.) The Jinan Golden Bridge team collaborates with you to identify and clarify such needs and requirements to guarantee the smooth and hassle-free incorporation of the CNC voice system with the automation system in place.

Evaluating Your CNC Vacuum Pump Integration

Integration of automated vacuum pumps in your automation line is vital to ensuring no operational hurdles arise. CNC vacuum pumps from Jinan Golden Bridge operate with a CNC Machine, robotic arms, and conveyor systems, amongst others. Identify clogs in interface protocols, and consider variations with regard to dimensions and power to eliminate CNC vacuum pump fitting problems. Engineering teams within the company modify designs to CNC vacuum pumps to eliminate compatibility issues. Picking pumps that are integrated with engineering systems as optimized CNC vacuum pumps mitigates installation hurdles and reduces the possibility of system demand conflicts.

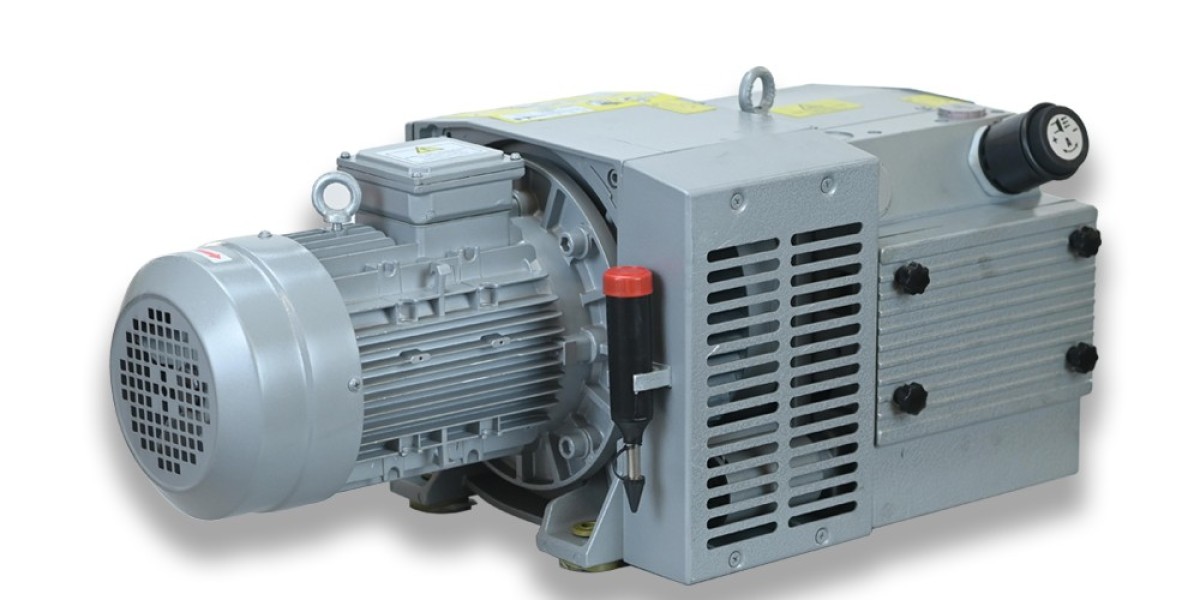

Prioritize Durability for Continuous Automation Tasks

Precision industrial automation usually runs 24/7, so the CNC vacuum pump must be tough enough to handle such rugged automation for the long term. Jinan Golden Bridge's CNC vacuum pumps are manufactured out of the finest materials, with the finest of craftsmanship to control the tolerances across the 4156 square meter, dust controlled work shop, under strict guiding principles of control for quality. Such powerful construction means that the CNC vacuum pump will resist the ongoing degradations of failure and maintain their work for ongoing extended use without stopping. Look for a CNC vacuum pump where \Jinan Golden Bridge\ will end up assisting you in places for where their products have gone thru testing across many different, high precision automation environments, so that reliable products will be available for automation without stopping.

Think About Energy Efficiency and Operation Expenses

When it comes to savings in the automation of the industry, energy efficiency should be the focus. Jinan Golden Bridge manufactures CNC vacuum pumps that deliver amazing energy efficient power and energy performance. This design results in lower utility bills and smaller carbon footprints and contributes to the goals of sustainable automation. This energy efficient CNC vacuum pump is offered at competitive prices because there is no middle man cost due to the fact that Jinan Golden Bridge is the direct manufacturer. Besides, think of how much you can save on maintenance: their CNC vacuum pumps are low maintenance, which is critical for automation systems that run continuously. This saves on costs and downtime.

Manufacturer’s Expertise Needs Verification

When talking about what contributes to the efficiency and longevity of your CNC vacuum pump, the company’s experience and support are key factors. Jinan Golden Bridge has experience spanning over a decade, producing CNC vacuum pumps for high-precision operations, and has customers from all over the world, i.e., 69+ countries. Out of the 34 professionals, each has advantageous skill sets and offers guidance in all technical aspects from selection, installation, to after-sales support. The company’s global support network offers maintenance, troubleshooting support, and spare parts. Working with a manufacturer, such as Jinan Golden Bridge, with appropriate experience means that you can expect not only a CNC vacuum pump, but also quality and dependable service.

Consider Customization for Your Unique Automation Needs

Fully customized offerings are often more profitable than mass customization, which means vacuum CNC routers will never be able to provide all the benefits you need, to the extent needed. Temperature, size, and suction capacity are the extremes one can encounter. As the engineering team works with you to understand the problem, the parameters will require the CNC vacuum pumps to be customized to the problem at hand. This means you can fully capture the pain-loss ratio associated with the counteract CNC vacuum pumps, which means you'll have a lower ratio of loss relative to the gain. Working with a custom CNC router manufacturer like Jinan Golden Bridge will provide significant benefits, especially for high-precision tasks.