In today's rapidly evolving industrial landscape, the demand for versatile and efficient equipment is paramount. Customizable centrifuges have emerged as a vital solution, addressing the unique needs of various sectors, from pharmaceuticals to food processing. These advanced machines not only enhance productivity but also ensure that specific operational requirements are met with precision. This article delves into how customizable centrifuges can significantly benefit industries by offering tailored solutions that optimize performance and results.

Understanding Customizable Centrifuges

Customizable centrifuges are engineered to adapt to the specific needs of different industries. Unlike standard models, these centrifuges allow users to modify various aspects, including speed, capacity, and rotor types. This adaptability ensures that businesses can select the ideal configuration for their unique processes, enhancing efficiency and output. For instance, in the pharmaceutical industry, the ability to customize the centrifuge's settings can lead to improved separation of cellular components, thereby increasing the yield of valuable products.

Enhancing Efficiency in Pharmaceutical Applications

In the pharmaceutical sector, the purity and yield of bioproducts are critical. Customizable centrifuges play a crucial role in this context. By allowing precise control over parameters such as g-force and temperature, these centrifuges facilitate optimal separation of components. For example, when processing cell cultures, the ability to adjust the rotor speed can lead to better clarification of the supernatant, resulting in higher recovery rates of active pharmaceutical ingredients. This level of customization not only boosts productivity but also enhances the overall quality of the final product.

The food processing industry also benefits significantly from customizable centrifuges. Different food products require specific separation techniques, and a one-size-fits-all approach often falls short. Customizable centrifuges can be tailored to handle various materials, from dairy products to vegetable oils. By adjusting the rotor design and operational parameters, manufacturers can achieve optimal separation and clarification, ensuring that the final products meet stringent quality standards. This flexibility is essential for maintaining competitive advantage in a market where consumer preferences are constantly evolving.

In biotechnology, the need for precision and reliability is paramount. Customizable centrifuges are invaluable in this field, where they are used for processes such as protein purification and cell harvesting. The ability to modify the centrifuge's settings allows researchers to optimize their workflows, reducing processing times and improving yield. Moreover, the integration of advanced monitoring systems ensures that each run is consistent, providing researchers with the confidence needed to produce high-quality results. This adaptability is a game-changer for laboratories aiming to accelerate their research and development efforts.

The Role of Customizable Centrifuges in Environmental Applications

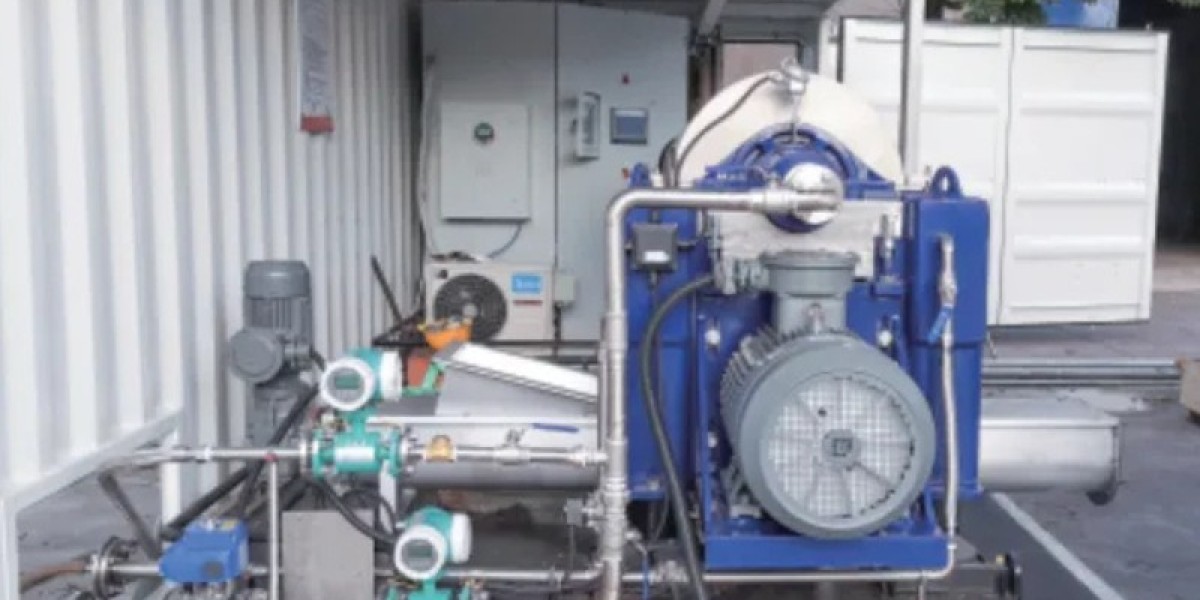

Environmental science is another field where customizable centrifuges are making a significant impact. From wastewater treatment to the analysis of soil samples, these machines can be tailored to meet the specific requirements of various environmental processes. For instance, in wastewater treatment, the ability to customize the centrifuge to handle different sludge types can enhance the efficiency of solids separation, leading to cleaner effluent and reduced environmental impact. This adaptability is crucial as industries strive to meet regulatory standards and minimize their ecological footprint.

In conclusion, customizable centrifuges represent a significant advancement in industrial technology, offering tailored solutions that meet the diverse needs of various sectors. Their ability to adapt to specific requirements not only enhances efficiency but also drives innovation across industries. As businesses continue to seek ways to optimize their processes and improve product quality, the role of customizable centrifuges will undoubtedly become even more prominent. Investing in these advanced machines is a strategic move for any company aiming to stay competitive in a dynamic market.