What Is Fiberglass Reinforcement?

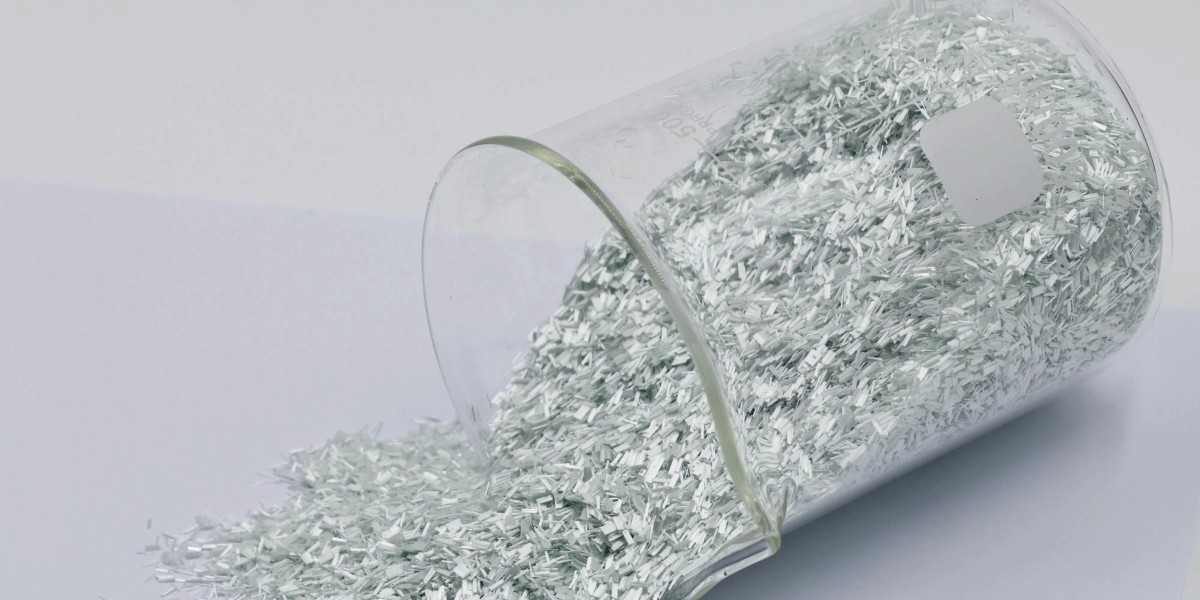

Fiberglass reinforcement is a key component in manufacturing Fiber-Reinforced Polymer (FRP) products, celebrated for its exceptional combination of strength, light weight, and durability. Made from fine glass fibers woven or formed into various structures—such as woven rovings, chopped strand mats, and chopped strands—it acts as a reinforcing backbone that boosts the mechanical properties of FRP materials. Unlike traditional materials like steel or aluminum, fiberglass reinforcement offers superior corrosion resistance, electrical insulation, and design flexibility, making it a game-changer for industries seeking reliable, long-lasting solutions. Whether used in structural components or precision parts, it delivers consistent performance that stands up to harsh environments, from chemical exposure to extreme temperatures. For businesses aiming to build competitive products, fiberglass reinforcement is more than a material—it’s a strategic investment in quality and efficiency.

Core Properties of Fiberglass Reinforcement for FRP Products

The appeal of fiberglass reinforcement in FRP products stems from its standout properties that address critical industry needs. Its impressive strength-to-weight ratio means FRP products reinforced with fiberglass are strong enough to replace heavier materials while reducing overall product weight, a crucial advantage in transportation and aerospace applications. Corrosion resistance is another key benefit—unlike metal, fiberglass doesn’t rust or degrade when exposed to chemicals, moisture, or saltwater, making it ideal for chemical processing equipment and marine structures. Additionally, fiberglass reinforcement offers excellent electrical insulation, making it a safe choice for electrical and electronic components. Its design flexibility allows manufacturers to create complex shapes and custom solutions, adapting to diverse project requirements. These properties work together to deliver FRP products that are durable, cost-effective, and high-performing.

Key Uses of Fiberglass Reinforcement in FRP Products Across Industries

Fiberglass reinforcement’s versatility makes it indispensable across a wide range of industries, with FRP products tailored to specific sector needs. In the aerospace industry, it’s used to manufacture lightweight, high-strength components like aircraft panels and interior structures, contributing to fuel efficiency and performance. The construction sector relies on FRP products reinforced with fiberglass for durable building materials such as roofing panels, wall cladding, and structural beams, which resist weathering and reduce maintenance costs. In transportation, it’s utilized in automotive parts, truck bodies, and ship hulls, offering corrosion resistance and weight reduction. The chemical industry benefits from its resistance to harsh substances, using FRP tanks, pipes, and valves for safe fluid handling. Even sports and leisure equipment—from surfboards to bicycle frames—incorporates fiberglass reinforcement for its balance of strength and flexibility. Infrastructure projects, including bridges and water treatment facilities, also leverage its durability to ensure long service life.

Why Choose Quality Fiberglass Reinforcement for Your FRP Products?

Investing in high-quality fiberglass reinforcement is essential to maximizing the performance and value of your FRP products. Superior fiberglass materials ensure consistent strength, durability, and reliability, reducing the risk of product failure and costly replacements. Quality reinforcement also enhances the efficiency of FRP manufacturing processes, as it integrates seamlessly with resins and other components. For businesses operating in competitive markets, using top-tier fiberglass reinforcement helps differentiate products by delivering better performance, longer lifespan, and lower total cost of ownership. Additionally, reputable suppliers of fiberglass reinforcement often provide professional technical support, helping you select the right product type—whether woven rovings, chopped strand mats, or chopped strands—for your specific application. By choosing quality, you’re not just buying a material; you’re partnering with a solution that drives customer satisfaction and business success.

Conclusion

Fiberglass reinforcement is the backbone of high-performance FRP products, offering a unique blend of strength, durability, corrosion resistance, and design flexibility. Its diverse applications across aerospace, construction, transportation, chemical processing, and more highlight its ability to meet the unique needs of various industries. By choosing quality fiberglass reinforcement, businesses can create FRP products that are lighter, more durable, and cost-effective, gaining a competitive edge in the market. Whether you’re developing precision aerospace components or durable infrastructure materials, fiberglass reinforcement delivers the reliability and performance that modern industries demand. It’s not just a material upgrade—it’s a strategic choice to build stronger, more competitive products that stand the test of time.