In the world of precision manufacturing, laser cutting has emerged as a game-changer, enabling intricate designs and high-quality finishes. However, the effectiveness of laser cutting relies heavily on the type of gas used during the process. This is where nitrogen generators come into play. By providing a consistent supply of nitrogen, these generators ensure that laser cutting operations achieve optimal performance, resulting in cleaner cuts and reduced operational costs.

The Role of Nitrogen in Laser Cutting

Nitrogen serves as an inert gas in laser cutting applications, which is crucial for preventing oxidation and ensuring a smooth cutting edge. When metal is cut with a laser, the intense heat can lead to oxidation, causing imperfections in the cut. By utilizing nitrogen generators, manufacturers can produce high-purity nitrogen on-site, eliminating the need for expensive gas deliveries and reducing downtime. This not only enhances the quality of the cuts but also streamlines the overall manufacturing process.

Cost Efficiency and Environmental Benefits

Investing in nitrogen generators for laser cutting can lead to significant cost savings. Traditional methods of sourcing nitrogen often involve high transportation costs and storage fees. In contrast, on-site nitrogen generation allows companies to produce nitrogen as needed, significantly lowering operational costs. Furthermore, this approach is environmentally friendly; it reduces the carbon footprint associated with transporting gas and minimizes waste associated with gas cylinders. As industries increasingly focus on sustainability, nitrogen generators represent a forward-thinking solution that aligns with eco-friendly practices.

Improving Production Efficiency

One of the standout advantages of nitrogen generators is their ability to enhance production efficiency. With a reliable supply of nitrogen, manufacturers can maintain continuous laser cutting operations without interruptions. This consistency not only improves productivity but also allows for better planning and scheduling of production runs. Additionally, the quality of the cuts achieved with nitrogen is superior, leading to less rework and scrap, ultimately saving time and resources.

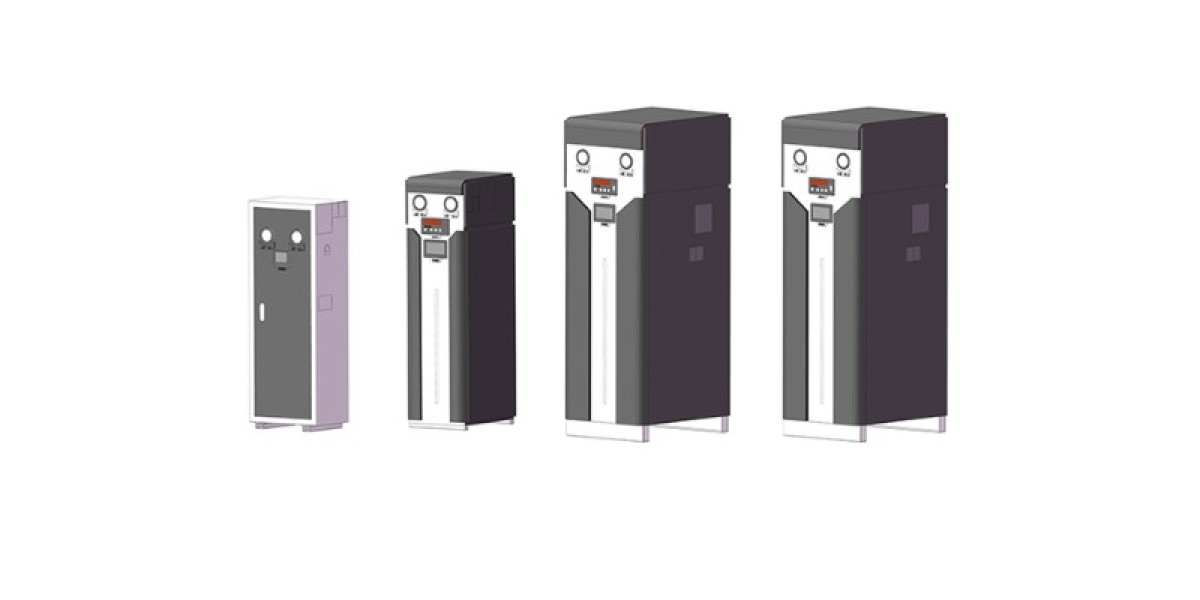

Nitrogen generators for laser cutting come in various sizes and configurations, making them suitable for businesses of all scales. Whether a small workshop or a large manufacturing facility, there is a nitrogen generator that can meet specific production needs. This scalability ensures that as a business grows, its nitrogen generation capabilities can expand accordingly, providing flexibility and adaptability to changing production demands.

In conclusion, nitrogen generators are essential for optimal laser cutting, offering numerous benefits that enhance both quality and efficiency. By providing a reliable source of nitrogen, these generators not only improve the cutting process but also contribute to significant cost savings and environmental sustainability. As industries continue to evolve, investing in nitrogen generation technology will undoubtedly be a pivotal step towards achieving operational excellence in laser cutting applications.