In the fast-paced world of food production and processing, efficiency and hygiene are paramount. Food-grade conveyors play a crucial role in ensuring that products move smoothly through various stages of production while maintaining the highest standards of safety and cleanliness. This article delves into the versatility of food-grade conveyors, highlighting their benefits and applications across different sectors of the food industry.

Understanding Food-Grade Conveyors

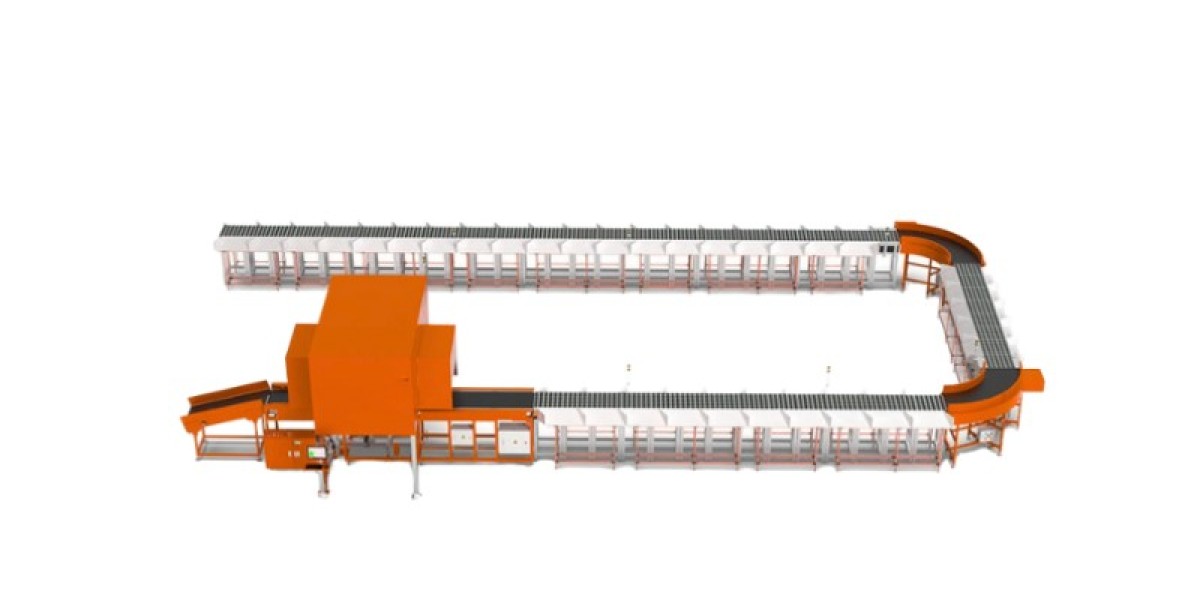

Food-grade conveyors are specifically designed to handle food products safely and efficiently. These conveyors are constructed from materials that meet stringent hygiene standards, ensuring that they do not contaminate the food being transported. This is particularly important in industries such as meat processing, dairy, and bakery, where the risk of contamination can lead to serious health issues. The versatility of food-grade conveyors allows them to be used in various applications, from transporting raw ingredients to packaging finished products.

Benefits of Food-Grade Conveyors

One of the primary advantages of food-grade conveyors is their ability to streamline production processes. By automating the movement of products, these conveyors reduce the need for manual handling, thereby minimizing the risk of contamination and increasing efficiency. Additionally, food-grade conveyors are designed for easy cleaning and maintenance, which is essential in the food industry where hygiene is critical. Their modular design allows for easy customization, enabling businesses to adapt the conveyor system to their specific needs.

Applications Across the Food Industry

Food-grade conveyors are utilized in a variety of sectors within the food industry. In meat processing, for example, these conveyors facilitate the movement of carcasses and cuts while ensuring that hygiene standards are upheld. In the dairy sector, food-grade conveyors are used to transport milk and cheese products, while in bakeries, they assist in the handling of dough and baked goods. The adaptability of food-grade conveyors makes them an invaluable asset in any food production line, contributing to overall operational efficiency.

Choosing the Right Food-Grade Conveyor

When selecting a food-grade conveyor, it is essential to consider several factors, including the type of food being handled, the production environment, and the specific requirements of the processing line. Different materials and designs are available to cater to various needs, ensuring that businesses can find a conveyor that meets their operational demands. Consulting with experts in food-grade conveyor systems can help organizations make informed decisions, ensuring they invest in the right equipment for their production needs.

Future Trends in Food-Grade Conveyors

As the food industry continues to evolve, so too does the technology behind food-grade conveyors. Innovations such as smart sensors and automation are becoming increasingly common, allowing for real-time monitoring and adjustments to be made during production. These advancements not only enhance efficiency but also improve safety and quality control. Businesses that embrace these trends will likely gain a competitive edge in the market, making food-grade conveyors an essential investment for the future.

In conclusion, food-grade conveyors are a vital component of the food production process, offering versatility and efficiency across various applications. Their ability to maintain hygiene standards while streamlining production makes them indispensable in the food industry. By investing in high-quality food-grade conveyors, businesses can enhance their operations, ensuring they deliver safe and high-quality products to consumers.