Handling powders and grains in industries such as food processing, pharmaceuticals, and agriculture can be a challenging task. The proper management and movement of these materials require specialized equipment to ensure smooth operations. One of the most critical components in this process is the Vacuum Duty Root Blower. These powerful machines are designed to handle bulk materials like powders and grains efficiently and effectively, improving the overall productivity and safety of the handling process.

What is a Vacuum Duty Root Blower?

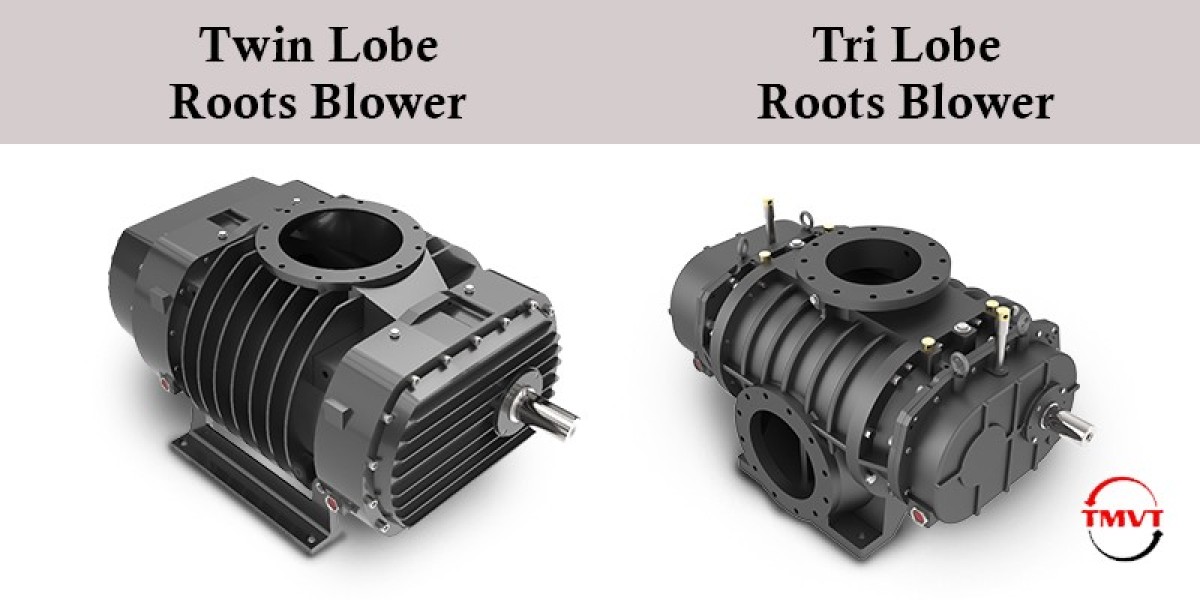

A Vacuum Duty Root Blower is a type of positive displacement blower used primarily in vacuum applications. It works by trapping air between two rotating lobes inside the blower, pushing the air through a system with precision and efficiency. In powder and grain handling systems, this blower generates the necessary vacuum pressure to transfer and move bulk materials through pipes and conveyors, often over long distances or vertical heights. Its robust design and ability to handle both vacuum and pressure operations make it an essential tool for industries dealing with powders, grains, and other dry materials.

Improving Efficiency in Powder and Grain Handling

When it comes to bulk material handling, efficiency is key. Powder and grain handling systems often face challenges related to material transfer, dust control, and energy consumption. By incorporating a Vacuum Duty Root Blower into these systems, many of these challenges can be addressed effectively. Here’s how:

1. Consistent and Reliable Material Flow

A Vacuum Duty Root Blower helps to maintain a steady and reliable flow of powders and grains, even in systems that require precise delivery. Whether it’s feeding a hopper, transporting grain to storage, or packaging powdered ingredients, the blower ensures that the materials move smoothly without clogging or interruptions. This consistency reduces downtime and increases the overall efficiency of the entire handling system.

2. Minimized Material Loss

In powder and grain handling systems, there is often a risk of material loss due to spillage, leakage, or inefficiency in the transfer process. A Vacuum Duty Root Blower significantly reduces these issues. By maintaining a stable vacuum pressure, the blower ensures that materials are transferred directly into the designated areas, minimizing the risk of spillage or loss. This is particularly important when handling high-value powders or grains, where minimizing waste can greatly impact profit margins.

3. Energy Efficiency

One of the most significant advantages of using a Vacuum Duty Root Blower in powder and grain handling systems is its energy efficiency. Unlike traditional air-moving equipment, which may require more power to operate, the Root Blower consumes less energy while still delivering high performance. This is particularly beneficial for businesses looking to reduce operational costs and improve sustainability. Lower energy consumption translates to reduced carbon footprints, helping businesses achieve their environmental goals while maintaining cost-effectiveness.

4. Enhanced Dust Control

Handling powders and grains can create a lot of dust, which can be hazardous to both the workers and the surrounding environment. Vacuum Duty Root Blowers help in controlling dust by ensuring that the materials are transported in a closed system, preventing dust from escaping into the air. This not only improves the working conditions for employees but also helps businesses comply with safety regulations and environmental standards related to dust emissions.

5. Durability and Low Maintenance

Powder and grain handling systems require equipment that can withstand continuous operation under demanding conditions. Vacuum Duty Root Blowers are built to last. With their heavy-duty construction and reliable performance, they can operate for extended periods with minimal maintenance. This durability reduces the need for frequent repairs or part replacements, saving businesses both time and money. Moreover, routine maintenance is straightforward, making these blowers a cost-effective long-term solution for bulk material handling.

6. Versatility and Customization

Another significant advantage of Vacuum Duty Root Blowers is their versatility. These blowers can be customized to fit various applications and industry needs. Whether you are handling grain in a silo, powder in a pharmaceutical facility, or bulk materials in a food processing plant, a Vacuum Duty Root Blower can be adapted to suit the specific requirements of your operation. This flexibility makes them a popular choice across various industries, as they can be tailored to provide optimal performance for any material-handling process.

Applications of Vacuum Duty Root Blowers

Vacuum Duty Root Blowers are used in a wide range of applications, including:

- Food and Beverage Industry: For transporting powders, grains, and ingredients, ensuring clean and efficient operations.

- Pharmaceutical Industry: For handling sensitive powders while maintaining the necessary hygienic standards.

- Agriculture: For transferring grains from storage bins to packaging systems.

- Chemical Processing: For conveying bulk powders and chemicals without contamination.

Conclusion

Incorporating a Vacuum Duty Root Blower into your powder and grain handling systems can dramatically improve efficiency, reduce energy consumption, and enhance operational reliability. Its ability to provide consistent material flow, minimize waste, and control dust makes it an essential component for industries dealing with bulk dry materials. The Vacuum Duty Root Blower is not just a valuable investment for today, but it also offers long-term benefits, reducing maintenance costs and improving the overall productivity of your operation.