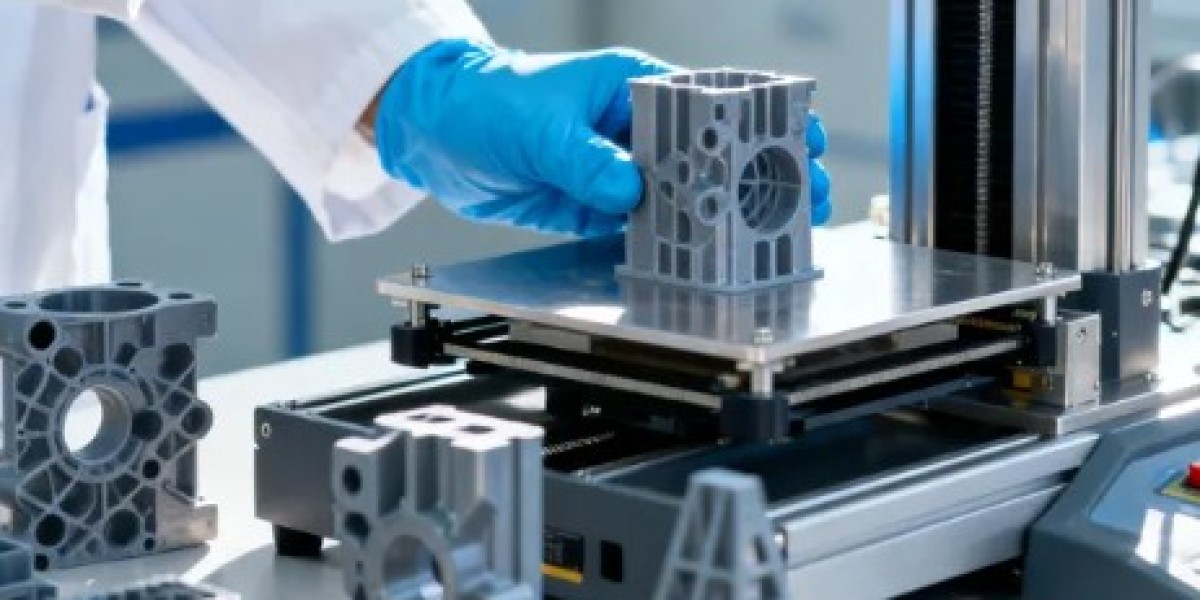

In recent years, metal additive manufacturing has emerged as a revolutionary technology that is reshaping the landscape of production across various industries. This innovative approach allows for the creation of complex geometries and lightweight structures that were previously unattainable with traditional manufacturing methods. By leveraging the capabilities of metal additive manufacturing, businesses can enhance their operational efficiency, reduce waste, and push the boundaries of design.

The Advantages of Metal Additive Manufacturing

One of the primary advantages of metal additive manufacturing is its ability to produce intricate designs that are not possible with conventional techniques. Traditional manufacturing often involves subtractive processes, which can limit the complexity of the final product. In contrast, metal additive manufacturing builds objects layer by layer, allowing for the creation of complex internal structures, lattice designs, and unique shapes. This capability not only expands design possibilities but also leads to significant weight reductions, which is crucial in industries such as aerospace and automotive.

Moreover, metal additive manufacturing significantly reduces material waste. In traditional manufacturing, a substantial amount of material is often removed during the machining process. However, with additive manufacturing, material is only used where it is needed, resulting in a more sustainable production process. This efficiency not only benefits the environment but also lowers production costs, making it an attractive option for manufacturers looking to optimize their operations.

Applications Across Industries

Metal additive manufacturing is finding applications in a variety of sectors, including aerospace, automotive, medical, and tooling. In the aerospace industry, for example, companies are utilizing this technology to produce lightweight components that enhance fuel efficiency and performance. The ability to create complex geometries allows for the integration of multiple functions into a single part, reducing the number of components required and simplifying assembly processes.

In the medical field, metal additive manufacturing is being used to create custom implants and prosthetics tailored to individual patient needs. This personalization not only improves patient outcomes but also accelerates the production timeline, enabling quicker responses to urgent medical needs. The versatility of metal additive manufacturing makes it an essential tool for innovation in healthcare.

Challenges and Future Directions

Despite its numerous advantages, metal additive manufacturing does face challenges that must be addressed for broader adoption. One significant hurdle is the need for advanced materials that can withstand the high temperatures and stresses involved in the additive process. Research and development in this area are ongoing, with a focus on creating new alloys and materials that enhance the performance and reliability of additively manufactured parts.

Additionally, the integration of metal additive manufacturing into existing production lines requires careful planning and investment in training for personnel. Companies must ensure that their workforce is equipped with the necessary skills to operate and maintain additive manufacturing equipment effectively. As the technology continues to evolve, ongoing education and adaptation will be critical for companies looking to remain competitive in the market.

Conclusion

In conclusion, metal additive manufacturing is undoubtedly shaping the future of production by offering unprecedented design flexibility, reducing material waste, and enabling rapid prototyping. As industries continue to explore the capabilities of this technology, it is clear that metal additive manufacturing will play a pivotal role in the evolution of manufacturing processes. By embracing this innovative approach, businesses can enhance their operational efficiency, drive sustainability, and remain at the forefront of their respective fields.