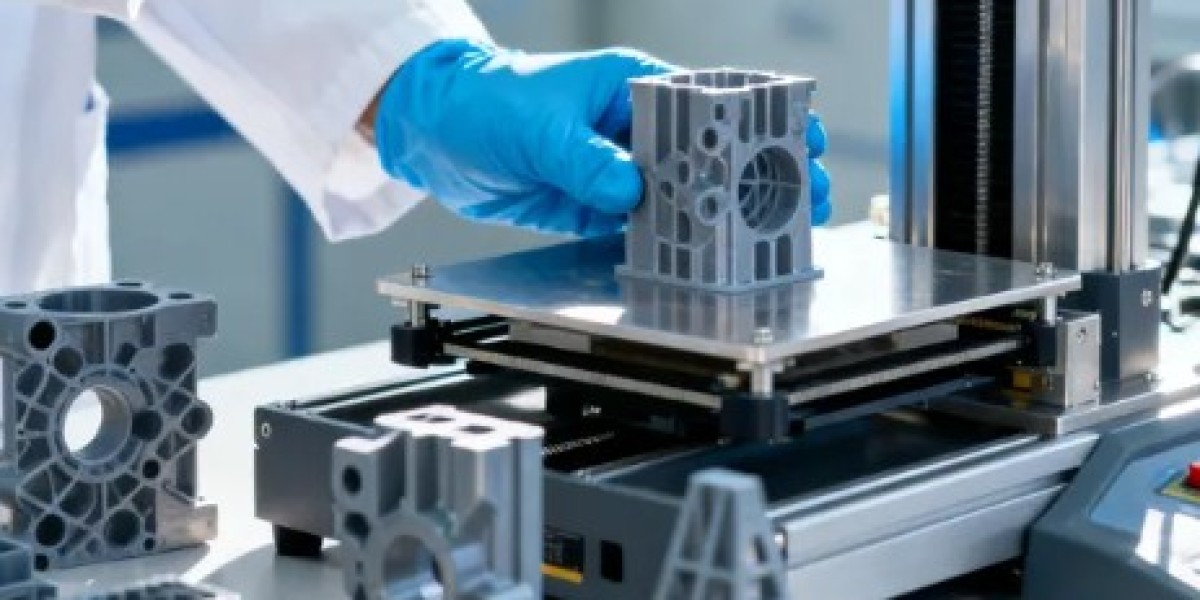

In the rapidly evolving landscape of modern manufacturing, CNC custom machining has emerged as a pivotal technology that drives efficiency and precision. This innovative process not only enhances the production capabilities of various industries but also allows for the creation of highly specialized components tailored to meet specific requirements. With the increasing demand for customized solutions, understanding the role of CNC custom machining becomes essential for businesses aiming to stay competitive in today's market.

CNC custom machining stands at the forefront of precision manufacturing. Utilizing computer numerical control technology, this process enables manufacturers to produce intricate parts with unparalleled accuracy. Unlike traditional machining methods, CNC custom machining minimizes human error, ensuring that each component meets the exact specifications required by clients. This level of precision is particularly crucial in industries such as aerospace, automotive, and medical devices, where even the slightest deviation can lead to significant consequences.

One of the primary advantages of CNC custom machining is its ability to produce complex geometries that would be nearly impossible to achieve with manual machining. This capability allows manufacturers to create innovative designs that enhance product functionality and performance. Additionally, CNC custom machining can significantly reduce production times, as multiple components can be machined simultaneously, streamlining the manufacturing process.Moreover, CNC custom machining offers flexibility in production runs. Whether a business requires a single prototype or a large batch of components, CNC machines can be easily reprogrammed to accommodate varying production needs. This adaptability not only saves time but also reduces costs associated with tooling and setup, making it an ideal choice for businesses of all sizes.

Quality control is paramount in manufacturing, and CNC custom machining excels in this aspect. Advanced CNC machines are equipped with precision measurement tools that ensure each part is produced to the highest standards. Regular calibration and maintenance of these machines further guarantee consistent quality, which is vital for building trust with clients and maintaining a strong reputation in the market.Additionally, the use of high-quality materials in CNC custom machining processes contributes to the durability and reliability of the final products. Manufacturers can choose from a wide range of materials, including metals, plastics, and composites, allowing them to select the best options for their specific applications.

As technology continues to advance, the future of CNC custom machining looks promising. Innovations such as artificial intelligence and machine learning are being integrated into CNC systems, enhancing their capabilities and efficiency. These advancements will not only improve production speeds but also enable smarter decision-making in the manufacturing process.Furthermore, the growing trend towards sustainability in manufacturing is influencing CNC custom machining practices. Manufacturers are increasingly focusing on reducing waste and optimizing resource usage, which aligns with the global push for environmentally friendly production methods. This shift not only benefits the planet but also appeals to consumers who prioritize sustainability in their purchasing decisions.

In conclusion, CNC custom machining plays a crucial role in modern manufacturing by offering precision, efficiency, and flexibility. Its ability to produce complex components with high accuracy makes it an invaluable asset for various industries. As technology continues to evolve, CNC custom machining will undoubtedly adapt, further enhancing its significance in the manufacturing landscape. For businesses looking to innovate and remain competitive, investing in CNC custom machining is not just an option; it is a necessity.