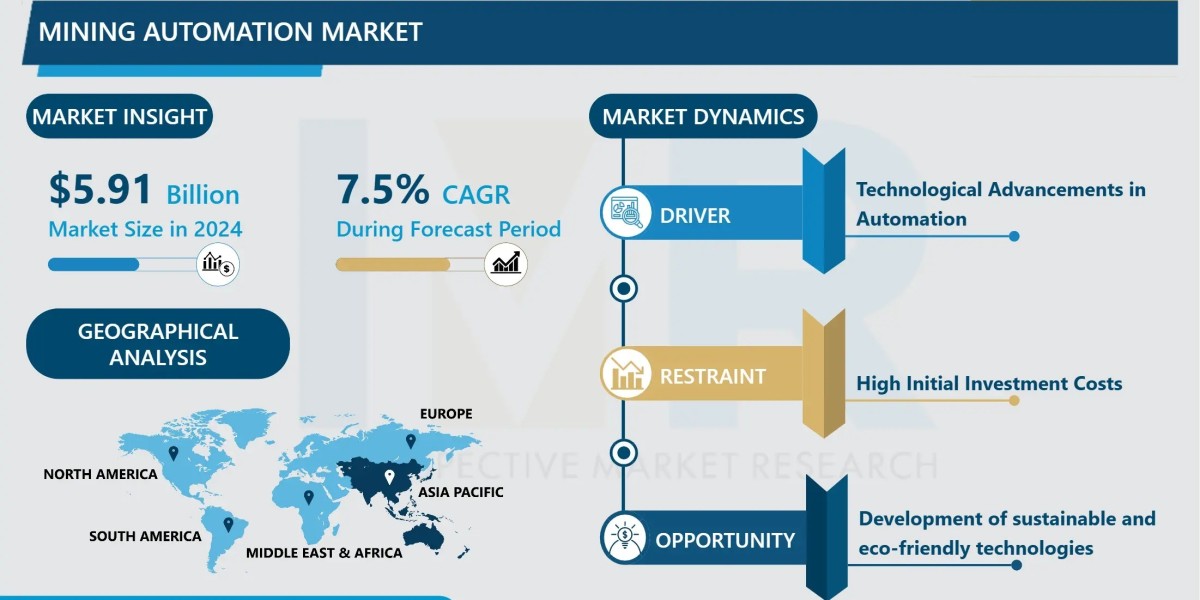

According to a new report published by Introspective Market Research, Mining Automation Market by Offering, Technique, and Application, The Global Mining Automation Market Size Was Valued at USD 5.91 Billion in 2024 and is Projected to Reach USD 10.54 Billion by 2032, Growing at a CAGR of 7.5%.

Market Overview

The global mining automation market is at the forefront of a technological revolution, fundamentally reshaping one of the world's oldest industries. Mining automation encompasses a suite of hardware, software, and robotic systems designed to operate mining equipment and processes with minimal human intervention. This includes autonomous haul trucks, drilling rigs, underground LHDs (Load-Haul-Dump), and centralized process control systems. The key advantages over traditional, manual mining are profound: significantly enhanced safety by removing personnel from hazardous environments, dramatically improved operational efficiency and consistency, reduced fuel and maintenance costs through optimized equipment use, and access to ore bodies that are too deep or dangerous for human miners.

Growth Driver

The most significant growth driver for the mining automation market is the persistent and critical industry imperative to enhance safety and overcome severe skilled labor shortages in remote and challenging mining locations. Mining is inherently dangerous, with risks of rock falls, explosions, and exposure to harmful gases. Automation directly addresses this by relocating workers from hazardous front-line roles to safe, remote control centers. Simultaneously, the industry faces a demographic challenge as experienced workers retire and attracting new talent to remote sites becomes difficult. Autonomous systems provide a reliable, 24/7 operational capability that is not constrained by shift patterns or human fatigue, ensuring continuous production and helping mining companies maintain output and viability in a tight labor market.

Market Opportunity

A substantial and transformative market opportunity lies in the integration of Artificial Intelligence (AI), machine learning, and advanced data analytics with core automation platforms. Beyond basic remote control, the next frontier is "smart mines" where AI algorithms analyze real-time data from sensors on equipment and within the mine to predict failures (predictive maintenance), dynamically optimize haulage routes for fuel efficiency, and even provide geological insights for better ore extraction. Furthermore, the development of fully integrated Mine-to-Mill automation solutions, which connect data from autonomous drilling and blasting directly to downstream processing plants to optimize crush size and recovery rates, presents a major value-creation opportunity for technology providers.

The Mining Automation Market is segmented on the basis of Offering, Technique, and Application.

Offering

The Offering segment is further classified into Hardware, Software, and Services. Among these, the Hardware segment, particularly autonomous and remote-controlled mining vehicles, accounts for the largest market share. This includes massive autonomous haul trucks, robotic drill rigs, and autonomous LHDs that form the physical backbone of automated operations. The high capital cost of this equipment and its direct role in core production activities make it the dominant revenue generator. However, the Software and Services segment is growing rapidly as the intelligence layer that enables and sustains these complex systems.

Application

The Application segment is further classified into Drilling, Hauling, Crushing, and Others. Among these, Autonomous Hauling is a dominant and highly visible application. The use of self-driving trucks in large surface mines (like those run by Rio Tinto, BHP, and Fortescue) has proven the technology's return on investment through reduced cycle times, lower fuel consumption, and eliminated operator-related variability. The success of haulage automation serves as a flagship for the broader industry transformation, driving adoption in other application areas.

Some of The Leading/Active Market Players Are-

- Caterpillar Inc. (USA)

- Komatsu Ltd. (Japan) [via its Frontrunner autonomous haulage system]

- Sandvik AB (Sweden)

- Epiroc AB (Sweden)

- Hitachi Construction Machinery Co., Ltd. (Japan)

- Hexagon AB (Sweden)

- Trimble Inc. (USA)

- Rockwell Automation, Inc. (USA)

- Siemens AG (Germany)

- ABB Ltd. (Switzerland)

- RPMGlobal Holdings Limited (Australia)

- Wenco International Mining Systems Ltd. (Canada) [A Hitachi subsidiary]

- “and other active players.”

Key Industry Developments

News 1:

In March 2024, Caterpillar announced that its autonomous haul trucks had moved a cumulative 10 billion tons of material globally, a milestone highlighting the massive scale and proven reliability of this technology in real-world mining operations over the past decade.

This achievement underscores the transition of autonomy from pilot projects to a mainstream, production-critical technology in surface mining.

News 2:

In February 2024, Epiroc launched a new generation of its battery-electric, autonomous Scooptram loaders for underground mining, combining zero-emission power with full automation for safer and more sustainable underground operations.

This development targets the growing demand for automation in the underground sector and aligns with the industry's dual goals of decarbonization and worker safety.

Key Findings of the Study

- Hardwareofferings (autonomous vehicles) and Hauling applications are the dominant revenue segments.

- The Asia-Pacificregion is the largest and fastest-growing market, driven by massive mining activity in Australia and increasing adoption in other countries.

- Growth is primarily driven by the need for improved safety and operational efficiencyand the challenge of skilled labor shortages.

- Key trends include the integration of AI for predictive analyticsand the convergence of automation with electrification for sustainable mining.