Material Safety Inspection of Xiamen Yizhou's Brace

For Xiamen Yizhou's brace, material safety inspection acts as a first line of defence, as far as safety, quality and reliability of the brace is concerned. Each and every raw material, including food grade silicone and EVA, is tested before the production begins. Testing is performed for Bisphenol A (BPA), as well as the evaluation of the heavy metal content (that complies with California Proposition 65), and the evaluation of the materials for biocompatibility. Materials were evaluated by a third party (Intertek) and found to be non toxic, non irritating, and lacking in harmful materials. While production is taking place, random checks of the materials that are in the process of being produced are conducted to evaluate and confirm safety. Xiamen Yizhou's brace is safe for long term oral use because of the strict material safety inspections.

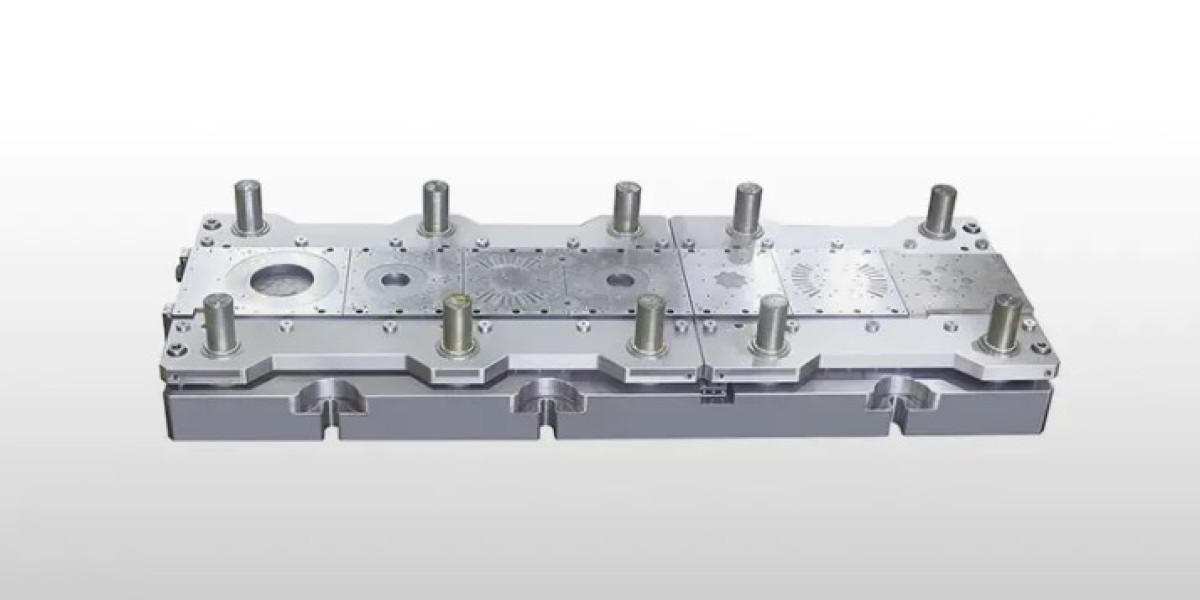

Xiamen Yizhou's Brace Inspection

Before sending out braces, Xiamen Yizhou does an inspection of the structural integrity of every brace. Using the most high-precision tools, the different types of structural defects, such as cracks, rough edges, and uneven thicknesses, are measured and documented. Using the appropriate factory length, width, and thickness specifications, the size of the brace's exterior is also measured to ensure that it accommodates the intended user group. Also checked is the bonded stitching to ensure that the components do not loosen or separate during the performance of their functions. In the case of moldable braces, structural integrity inspections are done to ensure that the brace is moldable and retains the required support and shape. This thorough inspection of structure eliminates any unfit or unapproved structural products.

Functional Performance Inspection of Xiamen Yizhou's Brace

Functional Performance Inspection is integral to the process of ensuring Xiamen Yizhou's brace is suitable to the user needs. Testing the flexibility and elasticity of the brace determines if the brace is able to comfortably and correctly positioned to provide adequate support. In braces where teeth whitening is an abrasive treatment, tests are done to find the chemical resistance of the brace to ensure the brace is non-reactive to the whitening agent. Testing the abrasiveness of the brace is an assessment of the long-term use of the brace to determine the brace's durability. Evaluating the breathability of the brace is done to provide comfort to the user during the long hours of wearing the brace. This functional inspection ensures that Xiamen Yizhou's brace performs well as expected.

Evaluation of Brace Fit & Comfort by Xiamen Yizhou

Prior to shipment, Yizhou Xiamen evaluates brace fit and comfort through simulated wear testing. Evaluators use standard oral models to determine how well the brace adapts to various dental anatomy. They perform checks on edge finishing to eliminate the possibility of gum and oral mucosa irritation. Fit tests for adult and teen specific sizes are done on models of the respective age group to ensure the fit is firm and comfortable. Testing feedback is used to refine design details to strike a balance between supportive and comfortable, thus ensuring acceptance and adherence.

Verification of Compliance & Certification for Xiamen Yizhou Brace

Xiamen Yizhou brace manufacturers, for each batch, determines adherence to the applicable International standards and certifications prior to shipment. Compliance to FDA Regulation (Registration Number: 3008763803) and the ISO 9001:2015 Quality Management System is confirmed by the Evaluator. Compliance of the product labeling and packaging to the Import & Export Guidelines is verified. Additional verification of custom braces is conducted to ensure compliance with customer requirements. Compliance determination ascertains that the Xiamen Yizhou brace may lawfully be traded and used within International markets.

Xiamen Yizhou's Brace Random Sampling and Batch Inspections

Xiamen Yizhou does random sampling and batch inspection processes to determine and ensure the quality of their products. There is a specific and determined rate of their products taken from each production batch for testing. Each test is conducted so that each inspection criterion is satisfied and tested. A batch inspection report is produced for each test so that they can document their findings and the report can display the history of the batch's quality. If there are any identify issues, the batch will be subject to re-inspection and any products that do not conform will be rejected. This type of random sampling and batch inspection will identify and issues so that all braces sent to customers from Xiamen Yizhou will meet their quality requirements.