As nations confront the dual challenges of crumbling electrical grids and urgent decarbonization goals, a critical yet underappreciated component is emerging as a linchpin for progress: the distribution Socket Box . From hurricane-battered coastal regions to sprawling solar farms, these systems are redefining how energy is managed in an era of climate volatility and renewable energy expansion.

Aging Grids Meet Modern Demands

The U.S. electrical grid, largely built in the mid-20th century, struggles to accommodate today’s renewable energy projects. Wind and solar installations face years-long delays to connect to transmission systems, with interconnection fees often rendering projects economically unviable1. Here, distribution socket boxes offer a solution. Their modular, weatherproof designs allow rapid deployment in remote areas, bypassing bottlenecks in outdated infrastructure. For instance, coastal microgrids now utilize corrosion-resistant enclosures rated for saltwater exposure, while wildfire-prone regions adopt flame-retardant models to prevent spark-induced disasters.

Enabling the Renewable Energy Surge

Solar and wind projects increasingly populate harsh environments—offshore platforms, arid deserts, and floodplains. Traditional infrastructure falters under these conditions, but modern distribution boxes integrate materials like reinforced polymers and stainless steel to withstand UV radiation, submersion, and temperature extremes. These innovations align with global initiatives like the EU Green Deal, which prioritizes resilient energy systems. By ensuring stable connections for decentralized energy sources, they help utilities meet net-zero targets without overhauling entire grids.

Smart Grids Demand Smarter Components

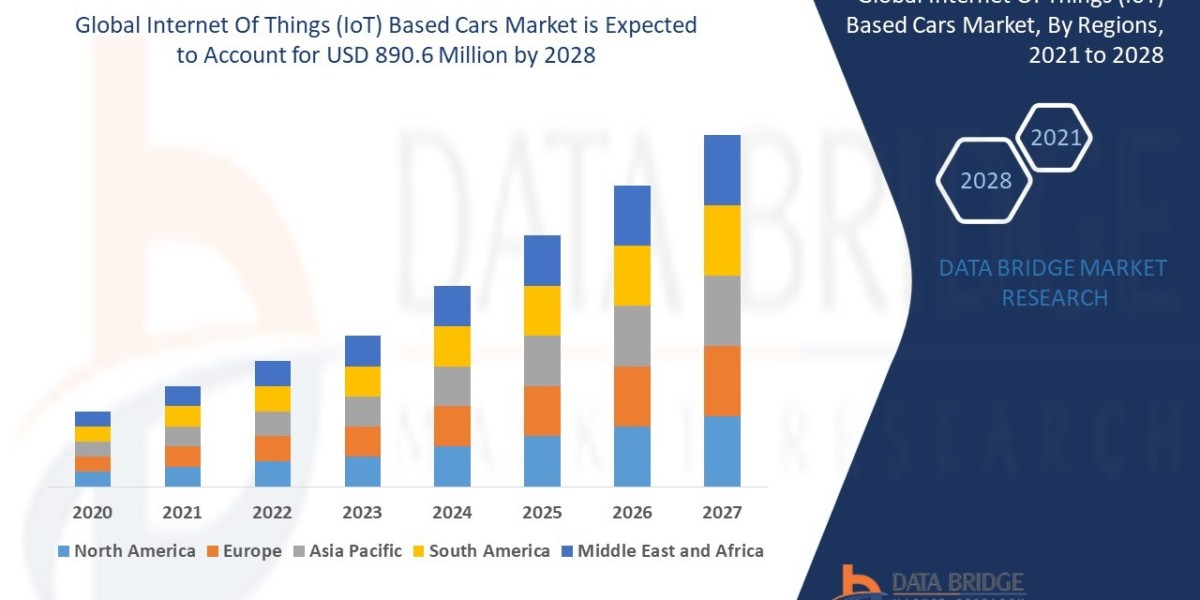

The rise of AI-driven grids and IoT technologies requires components that do more than transmit power. Advanced distribution boxes now embed sensors to monitor load fluctuations and thermal stress, enabling predictive maintenance for smart factories and urban EV networks. This real-time data flow minimizes downtime in automated production lines and supports dynamic energy routing during peak demand—a critical feature as data centers and electric vehicles strain existing systems.

Safety in Hazardous Environments

Industrial sectors like oil refining and mining face heightened risks from aging electrical systems. Explosion-proof distribution socket boxes, compliant with ATEX standards, prevent sparks in volatile atmospheres, protecting both workers and equipment. Their tamper-resistant designs also deter unauthorized access, addressing cybersecurity concerns in critical infrastructure.

The Path Forward: Modularity and Scalability

Geopolitical shifts toward localized manufacturing demand agile power solutions. Distribution socket boxes with standardized interfaces allow factories to expand capacity incrementally—essential for EV battery plants and semiconductor fabs racing to meet regional demand. This modularity also benefits disaster response; portable units restore power in refugee camps or storm-damaged areas within hours.

For industries navigating the intersection of sustainability and reliability, www.nante.com delivers distribution socket boxes engineered to bridge yesterday’s infrastructure with tomorrow’s energy needs. Their solutions exemplify how innovation in power distribution can drive both ecological resilience and industrial progress.