Understanding the Importance of Customizable Banana Roller Supplier in Web Handling Systems

In industrial manufacturing, the ability to control the movement and alignment of materials through various stages of processing is crucial. Whether it's for textiles, paper, film, or other materials, the process must be seamless to ensure high-quality output. This is where customizable banana rollers come into play. These specially designed rollers are indispensable in web handling systems, serving as essential components to maintain tension, alignment, and flatness during the production process.

A Banana Roller Supplier plays an integral role in ensuring that businesses have the right equipment to support their operations. In this article, we will explore the benefits of customizable banana rollers, their applications, and why partnering with the right supplier is key to maximizing efficiency.

What Are Banana Rollers?

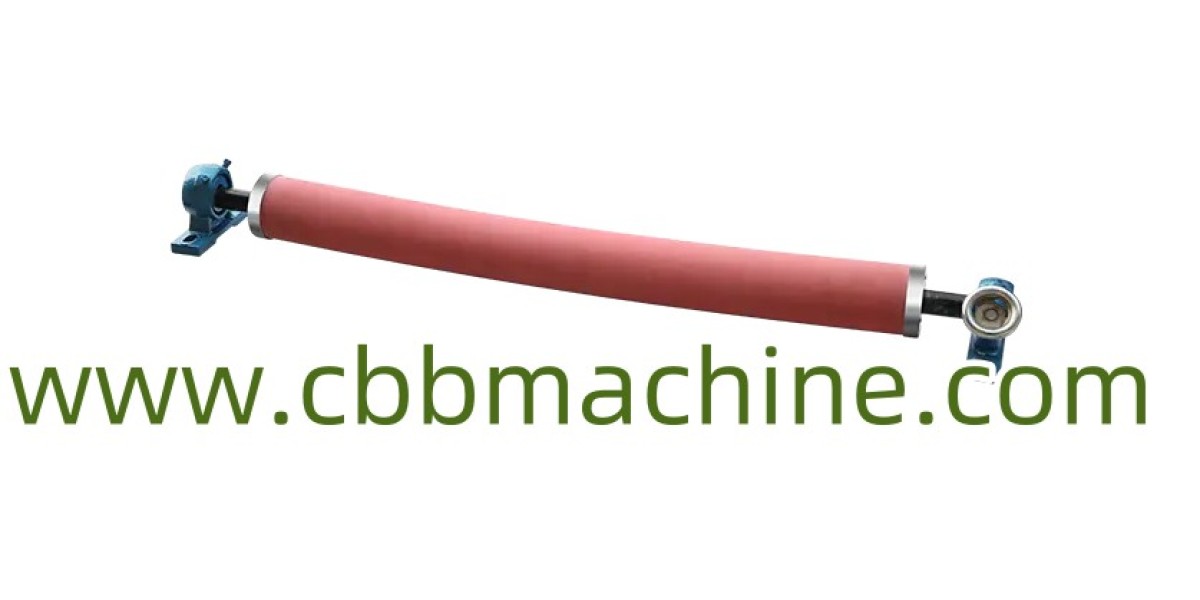

A banana roller, often referred to as a bowed roller, features a curved or bow-shaped structure. The unique design of the roller helps distribute tension evenly across the web, keeping materials such as paper, film, or textiles from wrinkling or misaligning. The primary function of a banana roller is to control the lateral movement of the web as it passes through various stages of processing, such as printing, cutting, or coating.

The name "banana roller" is derived from the shape of the roller, which resembles the curve of a banana. This shape allows the roller to exert controlled force along the web’s width, thus ensuring uniform tension throughout the process. Depending on the type of material being processed, the roller can be customized in terms of curvature, diameter, material composition, and surface coating.

Benefits of Customizable Banana Rollers

Precise Tension Control One of the most significant advantages of a banana roller is its ability to maintain precise tension control. By adjusting the curvature of the roller, a Banana Roller Supplier can create a customized solution that ensures uniform tension distribution across the entire width of the material. This is particularly important when working with materials that are sensitive to tension variations, such as thin films or delicate textiles.

Improved Material Alignment Misalignment of the material during processing can lead to defects and inefficiencies. A customizable banana roller helps keep the material properly aligned, preventing issues such as wrinkles, folds, or skewing. This alignment is essential in industries such as printing, packaging, and textiles, where even slight misalignment can impact the quality of the final product.

Increased Durability and Efficiency Customization allows manufacturers to select the most appropriate materials for the roller, ensuring longevity and durability. For example, high-quality coatings, such as chrome or rubber, can be applied to the roller’s surface to protect it from wear and tear. This increases the lifespan of the roller and reduces the need for frequent replacements, which, in turn, leads to improved operational efficiency.

Versatility Across Different Applications A Banana Roller Supplier can provide rollers suited for various applications. Whether you are working with paper, plastic, metal, or textiles, the customization options for banana rollers make them adaptable to different materials and processes. This versatility makes them an essential component in multiple industries, including packaging, printing, paper manufacturing, and textiles.

Reduced Downtime and Maintenance By investing in a high-quality customizable banana roller, businesses can reduce the likelihood of downtime caused by malfunctioning rollers. Customization ensures that the roller is suited to the specific needs of the production line, resulting in smoother operations and less frequent maintenance. This leads to cost savings and increased production uptime.

Customization Options for Banana Rollers

When selecting a Banana Roller Supplier, customization is an essential factor to consider. Some of the key aspects of roller customization include:

Curvature and Diameter: Depending on the material and the process, the curvature and diameter of the roller can be adjusted to meet specific tension requirements.

Material Composition: The roller's surface can be coated with different materials, such as chrome, rubber, or ceramic, to ensure compatibility with the material being processed.

Coating Types: Special coatings, such as anti-static coatings or corrosion-resistant finishes, can be applied to enhance the roller’s performance in specialized applications.

Roller Length and Width: The length and width of the roller can be tailored to fit the specific size of the production line, ensuring a perfect fit and optimal performance.

Why Partner with the Right Banana Roller Supplier?

Selecting the right Banana Roller Supplier is crucial to ensuring that your equipment meets the unique demands of your production line. The right supplier will not only provide high-quality rollers but also offer valuable insights and recommendations based on years of expertise in the field.

Here are a few reasons why it’s important to choose the right supplier:

Customization Expertise: A reputable supplier will have the experience and knowledge to create rollers tailored to your specific requirements. This expertise is essential for ensuring that the roller performs optimally in your production environment.

High-Quality Materials: A reliable supplier will use top-quality materials and coatings to manufacture the rollers, ensuring that they are durable and long-lasting.

Customer Support and Service: Ongoing support and maintenance services are essential to ensure that your banana rollers continue to perform efficiently over time. A dependable supplier will offer customer support to address any issues that may arise during operation.

Applications of Customizable Banana Rollers

Customizable banana rollers are used in various industries where web handling and material alignment are critical:

Packaging: In flexible packaging, banana rollers help ensure that films are aligned correctly during the printing and sealing processes.

Textile Manufacturing: In textile mills, banana rollers prevent fabric from wrinkling, ensuring smooth processing through dyeing, printing, and finishing.

Paper Industry: Banana rollers are widely used in the paper industry to prevent misalignment during cutting and slitting processes.

Printing: In printing presses, banana rollers are used to ensure that the paper or film moves smoothly, reducing the likelihood of print defects.

Conclusion

Customizable banana rollers are essential components for many industrial applications, providing precise tension control, material alignment, and durability. Partnering with a reputable Banana Roller Supplier ensures that your rollers are customized to meet the specific needs of your production process, ultimately leading to improved efficiency, reduced downtime, and higher-quality products.