Enhancing Web Handling Efficiency: The Role of a Banana Rollers Supplier

In many manufacturing industries, particularly those involved in converting, printing, laminating, and packaging, maintaining precise control over web tension and alignment is a critical component of ensuring product quality. One of the most effective tools used to achieve this control is the banana roller—a curved roller designed to spread and flatten materials such as films, foils, textiles, paper, and plastic sheets as they pass through machinery. For operations relying on continuous and wrinkle-free web processing, working with a professional Banana Rollers supplier is key to long-term success.

What Are Banana Rollers?

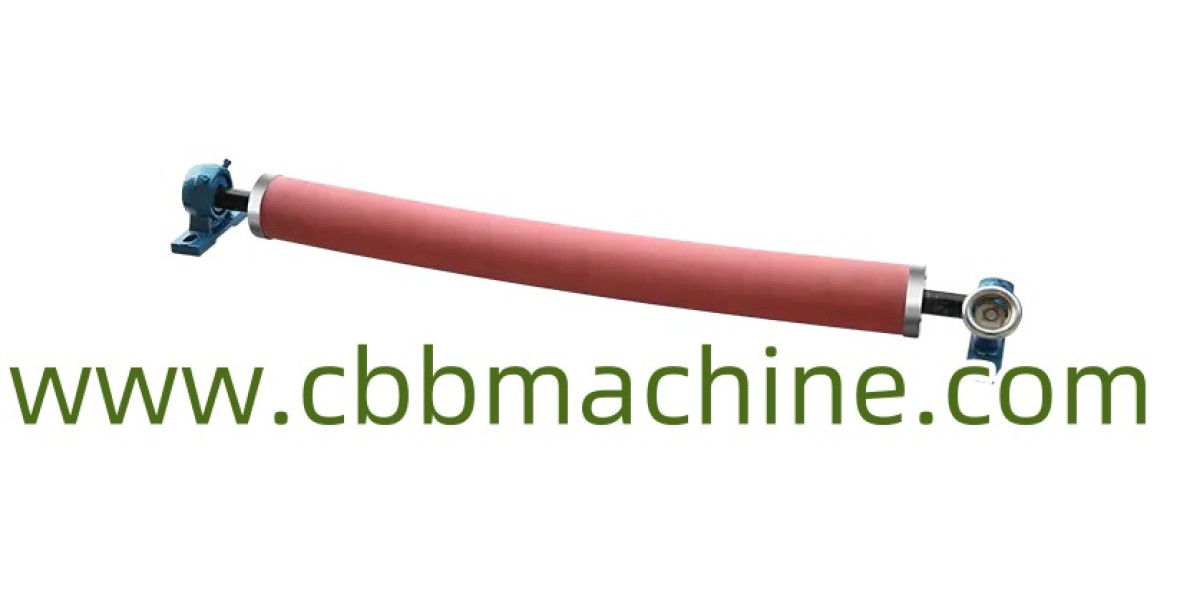

Banana rollers, also known as bowed rollers, are engineered with a gentle curve, giving them a “banana” shape that distinguishes them from traditional cylindrical rollers. This curvature helps to eliminate wrinkles, creases, and slack in various web materials during high-speed processing. They can be found in machines used in industries such as printing, coating, paper production, textile finishing, and flexible packaging.

By introducing lateral tension to the material, banana rollers stretch the web slightly as it passes over the roller, helping to align the edges and flatten the surface. This results in a more stable and consistent product with fewer production errors or rejections.

Why Work With a Banana Rollers Supplier?

When selecting equipment for a production line, quality, precision, and long-term reliability are vital. A trusted Banana Rollers supplier brings not only the product but also valuable expertise in roller design, manufacturing, and application. They understand how to customize banana rollers to suit specific machinery configurations and material types.

Working with an experienced supplier also ensures that the rollers meet critical requirements such as:

Proper bow angle for the application

Dynamic balancing for smooth operation

Surface treatments or coatings appropriate to the material

Shaft designs compatible with your existing systems

A supplier who specializes in banana rollers will also offer ongoing technical support, helping companies address issues related to roller positioning, wear, and maintenance.

Customization Makes a Difference

No two production lines are exactly the same. That’s why customization is an essential service offered by a capable Banana Rollers supplier. Variables such as the width of the web, tension levels, operating speed, and type of substrate all affect how the roller must be designed.

Suppliers typically offer customization for the following parameters:

Length and diameter of the roller

Bow curvature based on material properties

Material selection for shafts and covers (e.g., rubber, aluminum, or steel)

Mounting options to suit specific machine configurations

Tailored solutions help improve efficiency, reduce downtime, and extend the life of both the roller and the equipment in which it is used.

Choosing the Right Supplier

Not all suppliers provide the same level of quality and service. When searching for a Banana Rollers supplier, consider the following factors:

Experience and Specialization

A supplier with a track record of manufacturing and supplying banana rollers is more likely to deliver a solution that meets your technical needs.

Engineering Support

Look for a partner who offers design consultation and after-sales service. This ensures the rollers work well within your system and continue to do so over time.

Quality Materials

The durability and functionality of a banana roller depend on the raw materials used. A reliable supplier sources high-quality components and carries out rigorous quality checks.

Lead Time and Delivery

Production schedules can be disrupted by delayed shipments. A responsive and well-organized supplier will offer realistic lead times and consistent delivery performance.

Customization Capabilities

Standard products may not meet the specific needs of your equipment. Suppliers with flexible manufacturing can provide rollers that fit your requirements exactly.

The Industrial Impact of Quality Banana Rollers

Businesses that partner with a capable Banana Rollers supplier benefit from enhanced production efficiency, reduced material waste, and improved output quality. In sectors where continuous production is essential, the stability offered by properly installed and maintained banana rollers cannot be overstated.

Whether used in laminating lines or high-speed printing presses, these rollers help minimize web-related defects, cut down on manual intervention, and improve overall productivity. Their design may appear simple, but their impact is significant.

Conclusion

Banana rollers are essential components in the world of web handling. They play a quiet but powerful role in helping industries maintain smooth, aligned, and wrinkle-free production lines. Collaborating with an experienced Banana Rollers supplier ensures that these components are tailored to your operational needs, built to last, and supported with expert guidance. As competition and demand increase across manufacturing sectors, attention to detail—even in seemingly minor components like rollers—can set a business apart.