Working With a Banana Rollers Supplier to Improve Web Spreading Efficiency

A reliable Banana Rollers supplier plays an important role in modern web processing industries, where equipment performance and material control directly impact product quality and operational efficiency. Whether you are working with film, fabric, foil, paper, or nonwoven materials, banana rollers—also called bowed rollers—offer a practical solution for eliminating wrinkles and improving web tension during high-speed production.

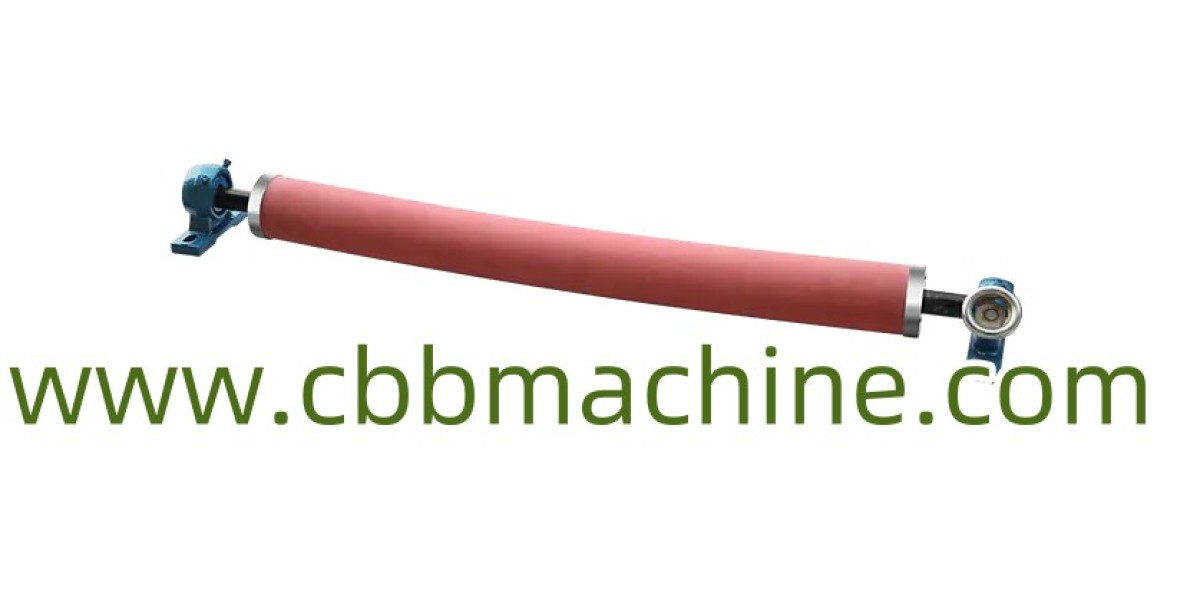

Banana rollers are engineered with a slight arc or curve along their shaft, which applies lateral stretching force as the web moves across their surface. This arc causes the web to spread outward from the center, reducing folds, slack, and misalignment. This function is critical in processes such as slitting, coating, laminating, rewinding, and printing, where even minor defects can result in material waste or production downtime.

How Banana Rollers Work

Banana rollers are mounted in positions where the web is likely to develop wrinkles or slack. As the web comes into contact with the curved roller, the difference in surface speed between the center and edges helps stretch the material slightly outward. This action aligns the material more evenly, creating a flatter, more consistent web before it enters the next stage of processing.

The performance of a banana roller depends on several variables, including the degree of bow, web width, line speed, material thickness, and tension settings. This is why customizable options are essential when sourcing from a Banana Rollers supplier.

Customization Options to Fit Unique Applications

Different industries and machine configurations require different roller specifications. A versatile supplier will offer customization in key areas such as:

Bow angle: Adjustable or fixed arc lengths to suit specific tension requirements

Roller length and diameter: Sized to fit your production line setup

Surface covering: Materials like rubber, polyurethane, or chrome to match web characteristics

Core materials: Lightweight aluminum for low-inertia systems or steel for heavy-duty applications

Mounting and bearing systems: Designed for specific environments, including high-temperature or dusty conditions

A tailored banana roller improves both machine compatibility and long-term performance. For instance, in flexible packaging lines, rollers with a rubber coating and a moderate bow angle are often used to gently handle thin plastic films without damaging the surface.

The Benefits of Using Banana Rollers in Production

The use of properly selected banana rollers can lead to multiple benefits across production processes:

Reduced web wrinkles and folds: A primary advantage that improves downstream operations like printing and sealing

Better tension control: Helps maintain even material distribution and prevents shifting during high-speed movement

Enhanced material appearance: Particularly important for visible product surfaces or transparent films

Lower material waste: Reducing defects can cut down on rejected rolls or rework

Smoother equipment operation: Prevents jams or misfeeds caused by poorly aligned material

These benefits result in more stable production output and cost savings over time, making banana rollers a critical component in modern manufacturing.

What to Expect From a Dependable Banana Rollers Supplier

A professional Banana Rollers supplier should provide both product quality and technical guidance. Their expertise helps you determine the optimal roller configuration based on your production goals and machinery type. They should also support you through every stage—from initial consultation and design to delivery and installation.

Key qualities to look for include:

Experience with various web materials: Knowledge of how different surfaces react to bowing pressure

Precision engineering: Rollers should be balanced for smooth rotation and vibration-free operation

Reliable lead times: Efficient order processing and clear communication

After-sales service: Support with installation advice and technical questions

Partnering with a knowledgeable supplier allows manufacturers to make confident decisions when upgrading existing lines or setting up new machinery.

Applications Across Various Industries

Banana rollers are used in many sectors, such as:

Packaging and labeling

Textile and nonwoven production

Printing and converting

Paper manufacturing

Film coating and lamination

Each application has specific web handling needs, and banana rollers can be adapted to meet those demands effectively. This versatility is one of the main reasons why these rollers are in high demand across industrial production facilities.

Conclusion

Banana rollers are a practical and efficient tool for improving web alignment, preventing wrinkles, and maintaining consistent material flow. Working with a dependable Banana Rollers supplier ensures that your rollers are precisely manufactured and tailored to meet the needs of your specific process. By investing in high-quality components and expert support, your production line can benefit from better material control and fewer disruptions, ultimately supporting greater operational efficiency.