Tubing is made by something known as the extrusion process. Process This technique is what makes long, hollow shapes such as tubing. Have you looked at a straw or a pipe? Some of those are products of the extrusion process.

It is important to appreciate the extrusion process used to make tubing. It’s as if you’re following a recipe for baking cookies. You have to know the right proportion of each ingredient and how to bake them at the right temperature. We use the extrusion to keep us from making crappy tubing.

Steps to Make Tubing

Step 1: Finding the Right Materials

To form tubing, we would have to pick a strong material. Just like you choose the right color for your drawings, we have to choose materials that are really durable and can hold things like water or air.

Step 2: Designing the Shape

Next we shape the tubing. We choose whether it will be thick or thin and whether it will have patterns. You can think of it as drawing a picture of what our tubing is going to look like. This is just to ensure we made our tubing for its purpose.

Step 3: Extruding the Tubing

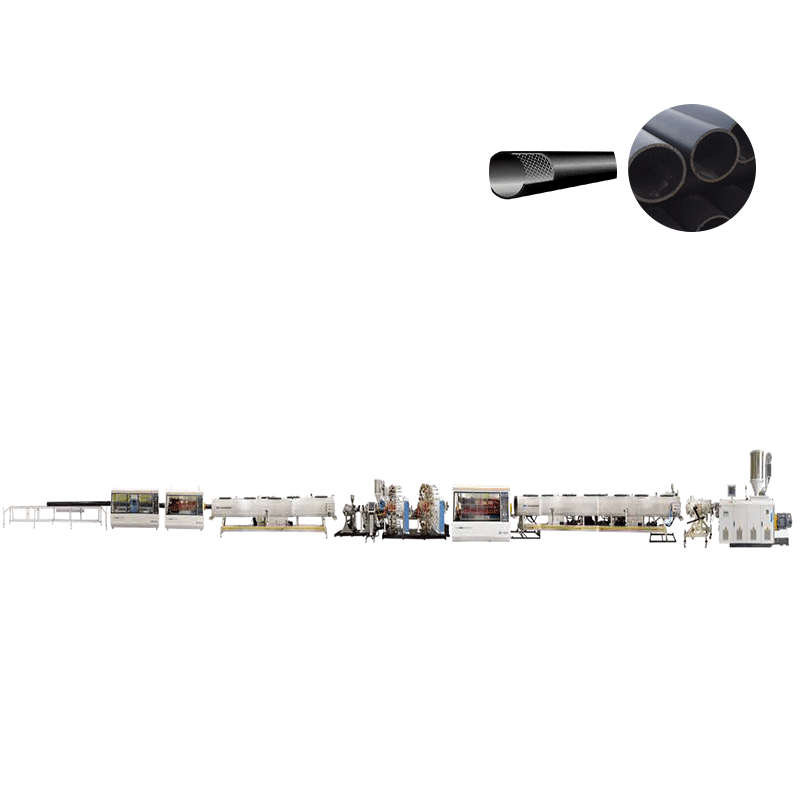

Let’s get to the fun part now, extruding that tubing! A tube extrusion machine is a special machine we use to push our materials through a shaped opening. It’s the toothpaste out of the tube deal. The materials come out in the form we crafted,” he says.

Material and Design Selection for Tube gridBagConstraints

Materials:

Because when we choose a material for tubes we have to think about what it will be used for. Is it going under water or over wires? Not all materials are equal, so we must select the best.

Design:

Creating the tubing is akin to drawing up a plan for a building. We consider how think the walls should be, and if it needs special features. The design is makes our tubing work just right.

Nothing ever goes as planned with tubing sometimes. Here are a few typical issues and how to address them:

Thickness Uneven: If some parts of the tube are thicker than other or thinner, we have to check the settings of the tube extrusion. Having things adjusted correctly can help.

Stranded Air: Air is sometimes trapped within the tube. To correct this we can modifies the temperature or the speed of the extruder.

Warping: The tubing can bend after being manufactured and we might have to adjust how we let it cool. Cooling it more uniformly could reduce warping.

Tips for Making Tubing

Keep Everything Clean: Making sure the extruder and materials are clean can help avoid getting any dirt into the tubing.

Test Before Production Before you start making a lot of tubing, it’s smart to test a small sample to ensure everything works right.

Team Player: Tubing is a team sport. Collaboration and conversation can make that process better.

By paying attention to these steps and tricks, high-quality tubing can be formed for use in almost any case. Just like practicing for a sport or hobby, practicing the Extrusion occurs every time, it helps us get better at making tubing. Jwell tube making machine is here for you to solve your problem about the tube!