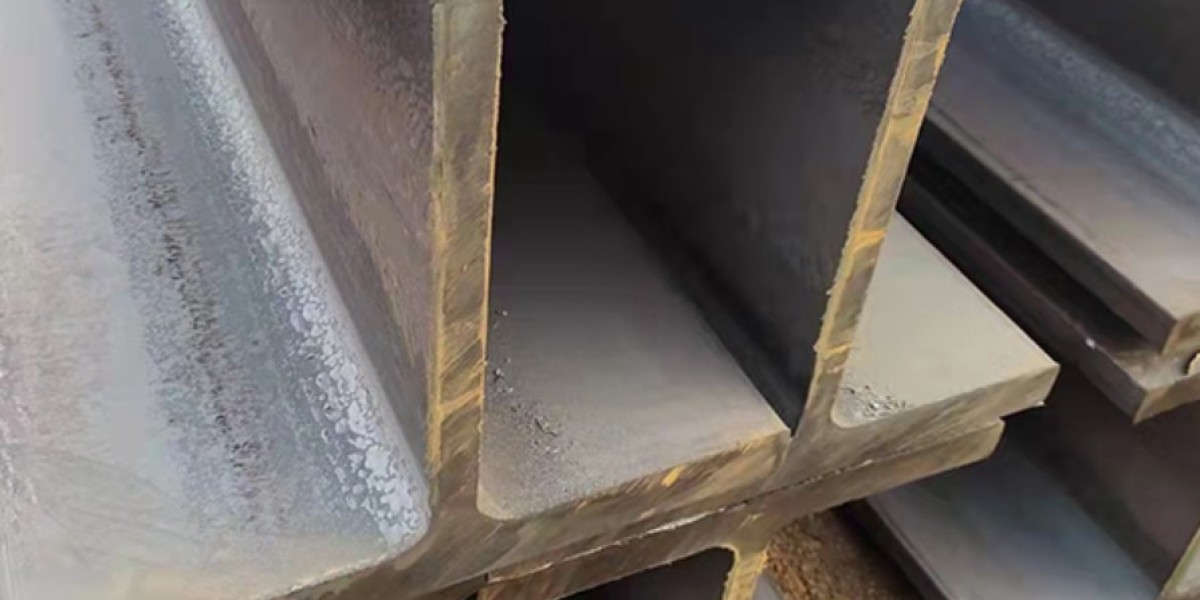

Steel I beams form the backbone of modern structural engineering, providing unmatched versatility in both building frameworks and bridge construction. Their distinctive shape - with two parallel flanges connected by a vertical web - creates an optimal balance of strength and material efficiency that has endured through generations of architectural innovation. From skyscrapers to highway overpasses, these structural components continue to enable increasingly ambitious engineering projects.

In building construction, I beams excel as primary load-bearing elements. Their configuration provides maximum stiffness with minimal weight, allowing for longer spans between supports than solid beams of equivalent mass. This characteristic proves particularly valuable in commercial structures where column-free spaces enhance functional flexibility. Modern steel mills produce steel i beam in standardized sizes up to 44 inches in depth, with custom rolling capabilities for specialized projects requiring non-standard dimensions. The predictable performance of these manufactured components simplifies structural calculations and accelerates construction timelines.

Bridge engineering has particularly benefited from I beam innovations. The development of weathering steel compositions has created I beams that form stable oxide coatings, eliminating the need for protective paint systems in many environments. Continuous span bridges utilize welded I beam assemblies that distribute loads efficiently across multiple supports. Some recent pedestrian bridge designs employ tapered I beams that vary in depth along their length, providing precisely calibrated strength where needed while minimizing material usage.

The manufacturing evolution of I beams has enhanced their structural performance. Computer-controlled rolling mills now produce beams with tighter dimensional tolerances, ensuring more consistent load-bearing characteristics. Improved welding techniques allow fabrication of built-up sections that combine multiple standard beams for extraordinary load requirements. Some producers offer H&I Beam with pre-engineered connection details that simplify field assembly while maintaining structural integrity.

Sustainability considerations have driven recent I beam advancements. The steel industry's progress in recycled content and energy-efficient production methods has reduced the environmental impact of these essential components. Designers increasingly specify beams that facilitate future disassembly and reuse, aligning with circular economy principles. As construction technologies evolve, steel I beam continue to adapt - maintaining their position as the fundamental building blocks of structural engineering while meeting the changing demands of 21st-century infrastructure.